Shaft couplings for your application

High performance and precision

What is a shaft coupling?

The primary function of a shaft coupling is to transmit torque, serving as a transmission element between two shaft ends, the input and output shaft. This connection can be classified into three classic types. They refers as force-fitting (the connection is made e.g. via clamping hubs), form-fitting (the force is transmitted by teeth or claws) or frictional (pressing between friction surfaces) connections. Requirements for the environmental conditions and the torque will further limit the selection options for selecting suitable couplings.

What are the advantages of flexible shaft couplings?

Shaft couplings ensure reliable and precise torque transmission, while compensating for vibrations that occur in the drive train and providing protection against overload situations. The coupling’s properties of compensating shaft misalignments and alignment failures, combined with the ability to absorb axial and radial misalignment, offer a wide range of possible applications.

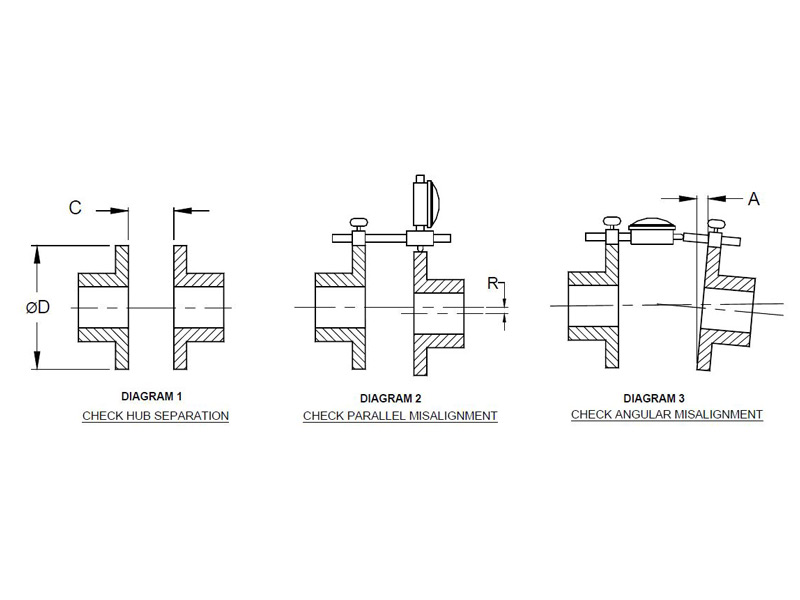

Shaft misalignments can generally be categorized as angular (angular), parallel (radial) and axial misalignments. Depending on the application specifications, different shaft couplings can be preferred. Common factors for selecting a preferred coupling include torque requirements, shaft diameter, available installation space and the application or operating range. With an ideal design, a shaft coupling protects the bearing and prevents sudden failures.

As a general recommendation, the misalignment value should not exceed one third of the maximum permissible value. Further shaft misalignments often occur during operation as a result of thermal expansion, wear in bearings and vibrations.

Where are shaft couplings installed?

Shaft couplings are used in a wide range of applications in almost every industry. From simple drives in textile, tool and packaging machines to highly complex positioning and high-speed applications, shaft couplings ensure smooth and reliable operation. Shaft couplings are used in mechanical engineering, medical technology, packaging machines, general automation and robotics applications.

In principle, there is a large range of shaft couplings:

Disc couplings: Backlash-free operation, very low inertia, large selection of connections, high torsional stiffness, easy installation, maintenance-free operation, ISO6 coupling designs suitable for cleanrooms (single cardanic, double cardanic)

Composite disc couplings: Electrical insulation properties, high chemical resistance, able to compensate high shaft misalignments, very low reaction forces, simple installation, backlash-free operation, high shock load capacity, ideally suited for reversing and indexing operation, low outgassing rate

Line Shaft coupling: High torsional stiffness, compensation of very large shaft misalignments, low reaction forces, backlash-free operation, versions up to 4,500 mm, two hub designs available (set screw version 6F and clamping ring version 6F-C)

Wind turbine products: Easy installation, maintenance-free operation, compensation of high shaft misalignments, long service life, robust product design, electrical insulation properties, low life cycle costs (LCC)

The composite disc coupling product line was specially developed for applications with high requirements in terms of large shaft misalignments, low reaction forces, precise positioning requirements and limited installation space.

As standard, all composite disc couplings offer up to three times the angular misalignment of disc or metal bellows couplings.

Do you have any questions and need personal advice? We will be happy to help you and look forward to hearing from you!