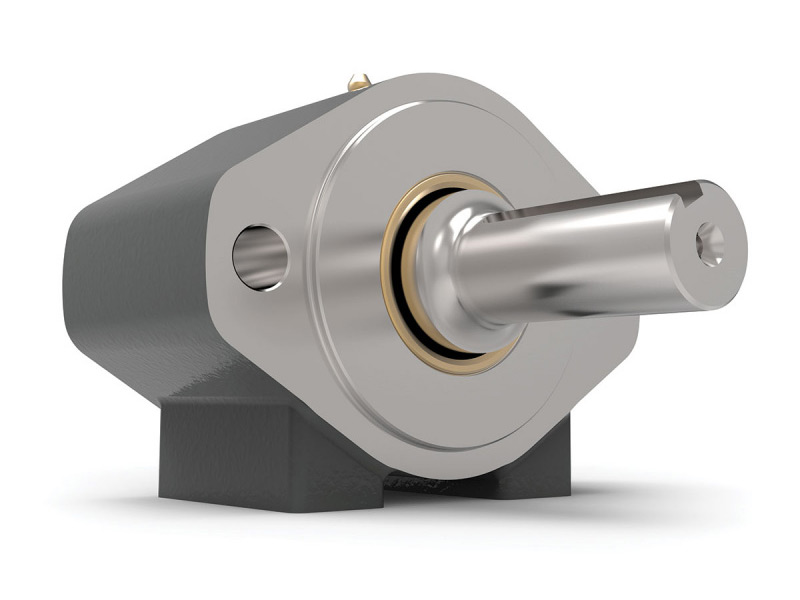

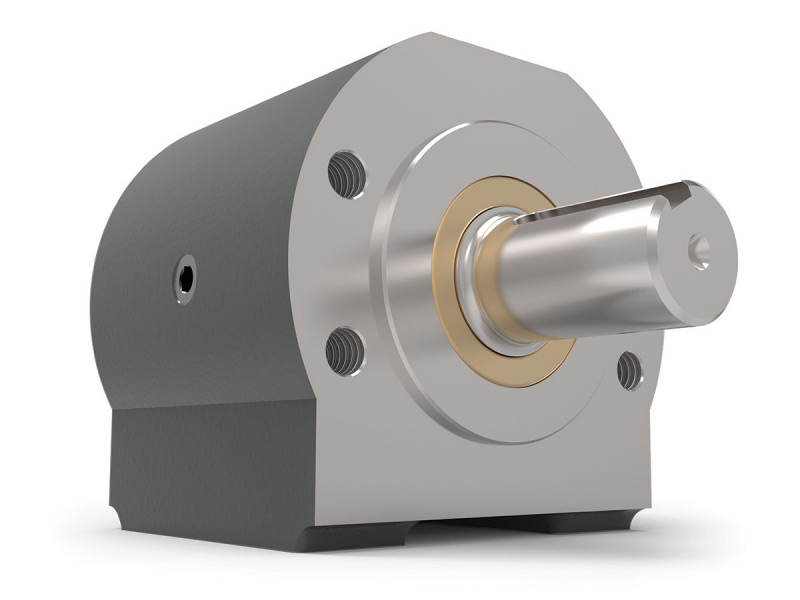

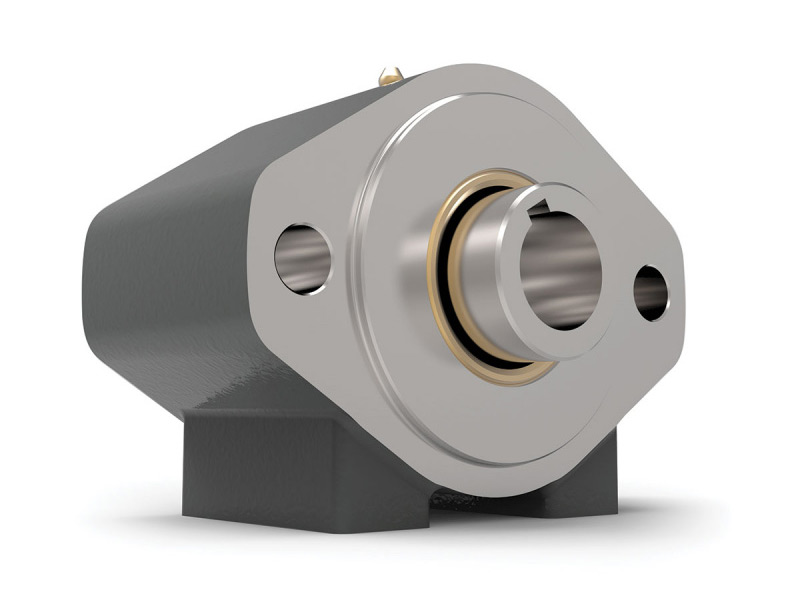

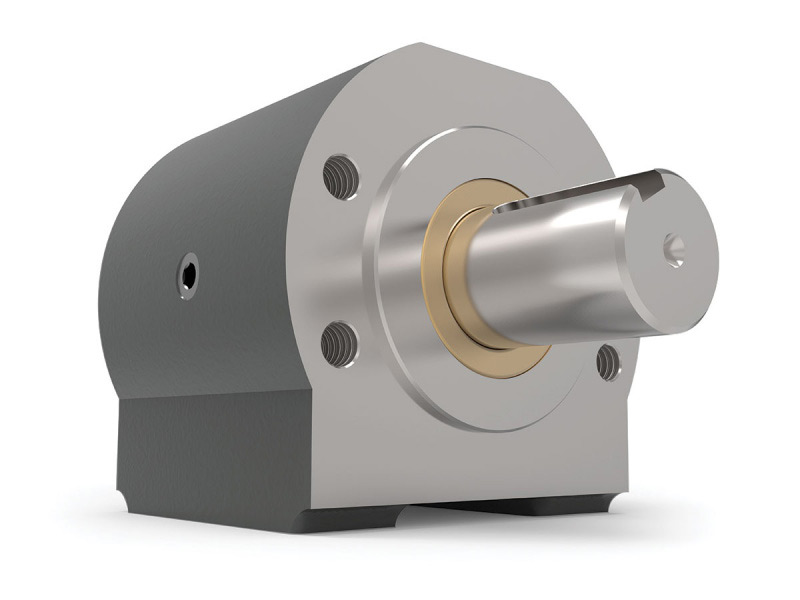

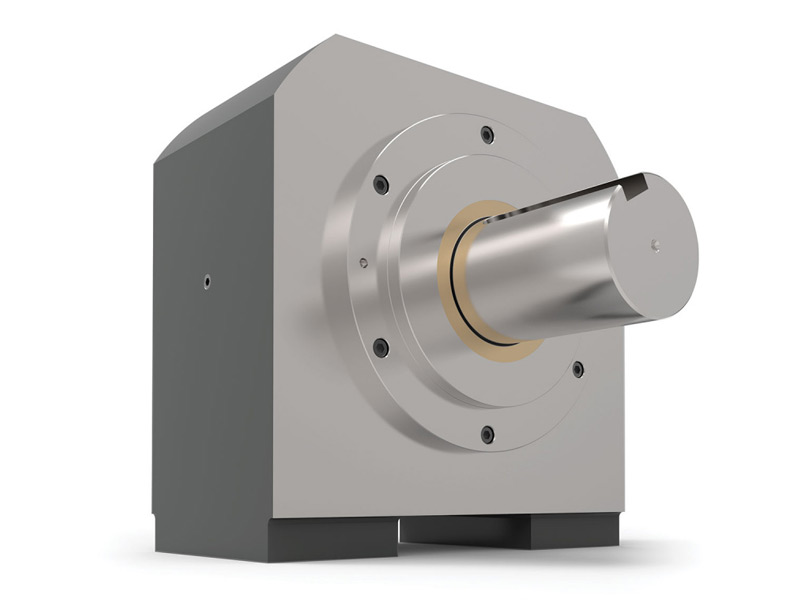

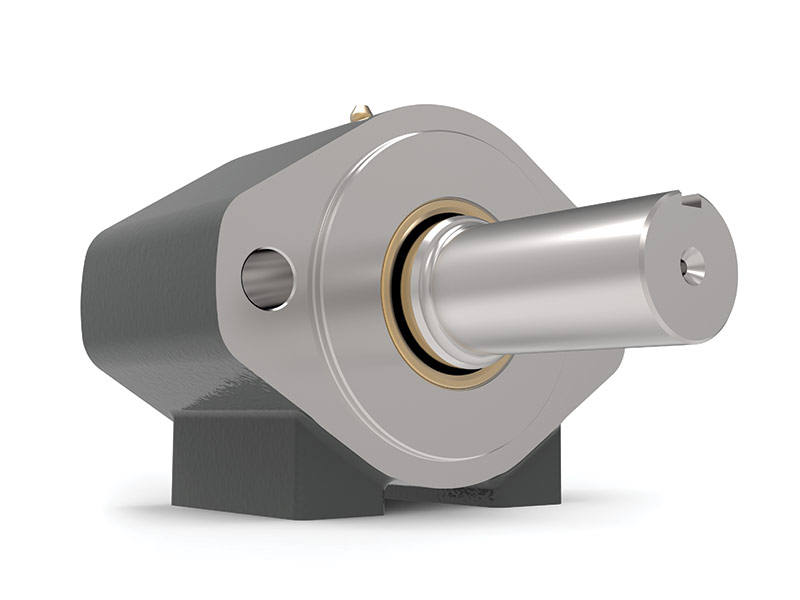

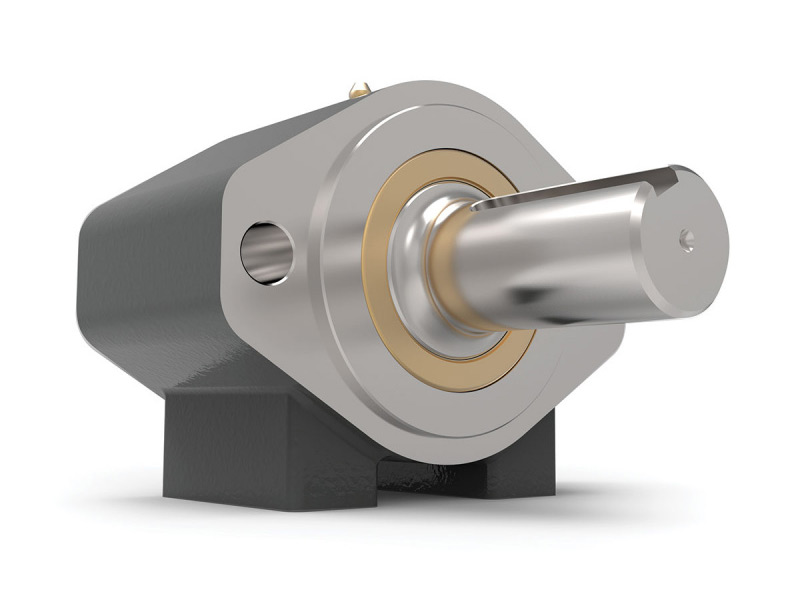

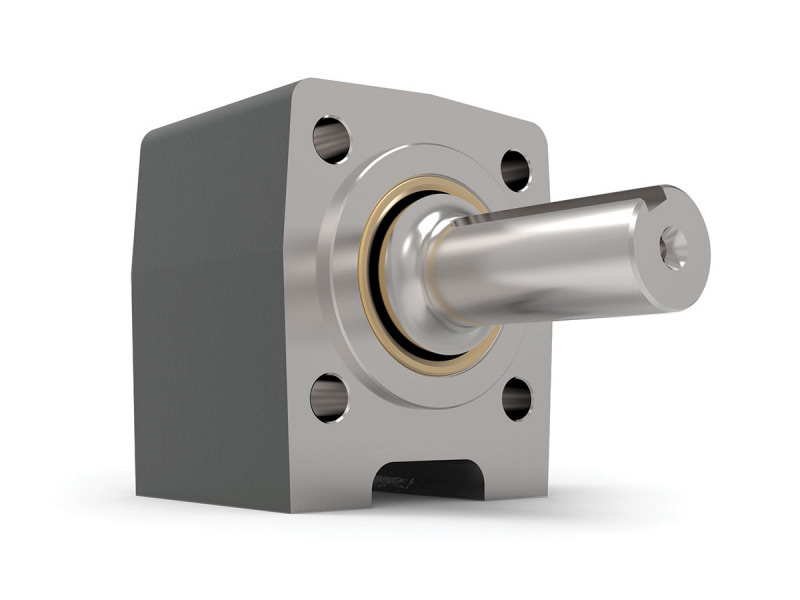

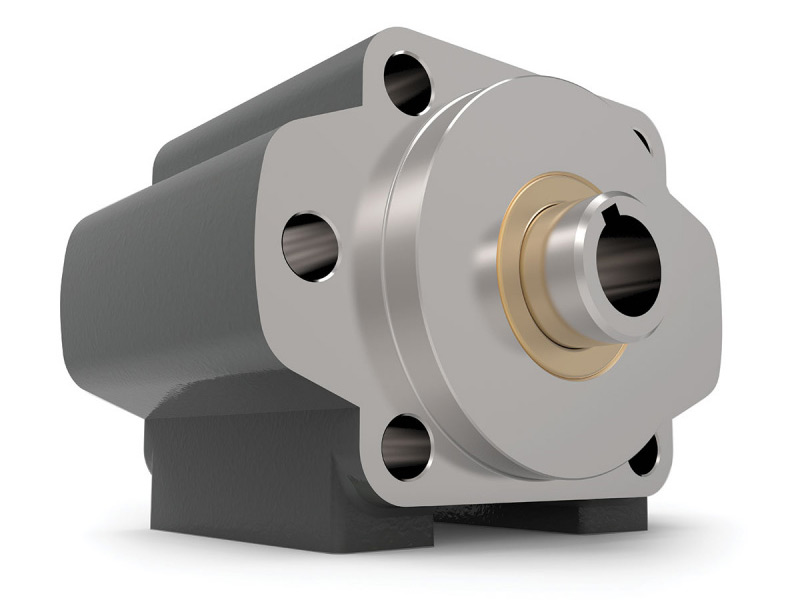

Overhung Load Adaptors

Protects against axial and radial loads

What is an overhung load adaptor (OHLA)?

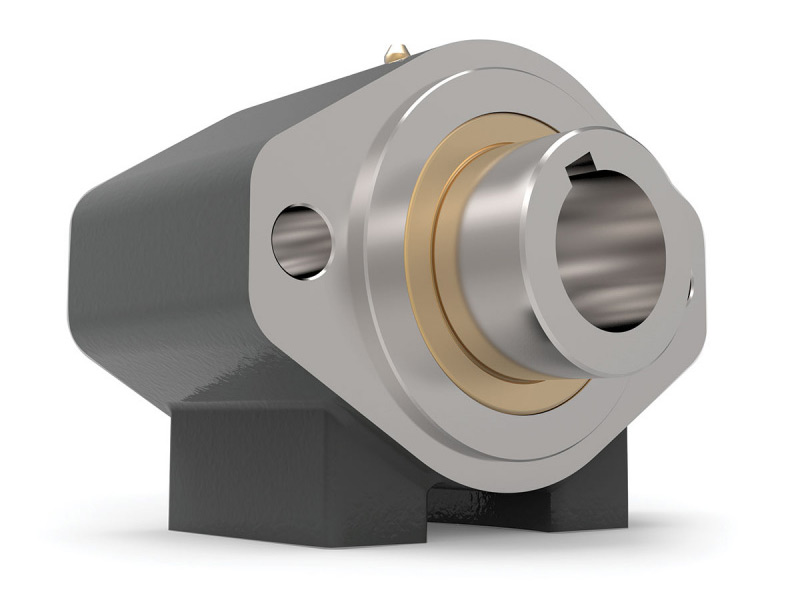

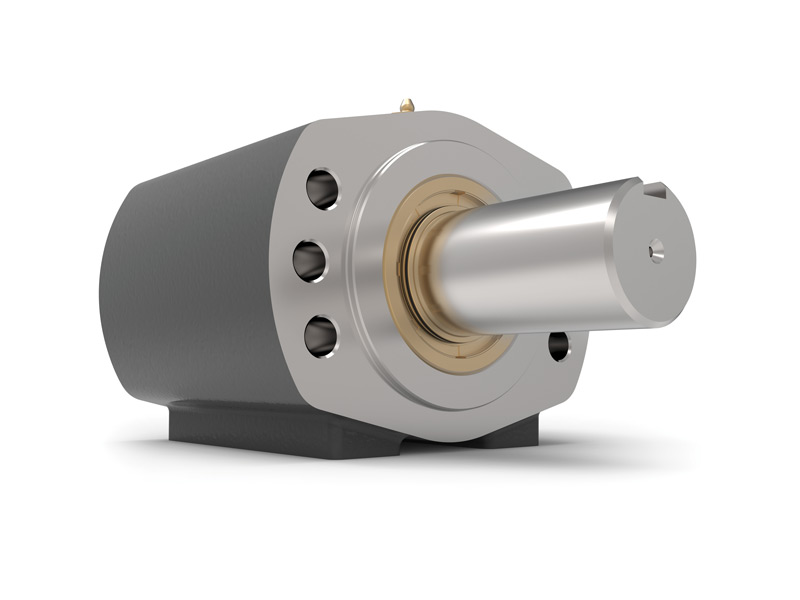

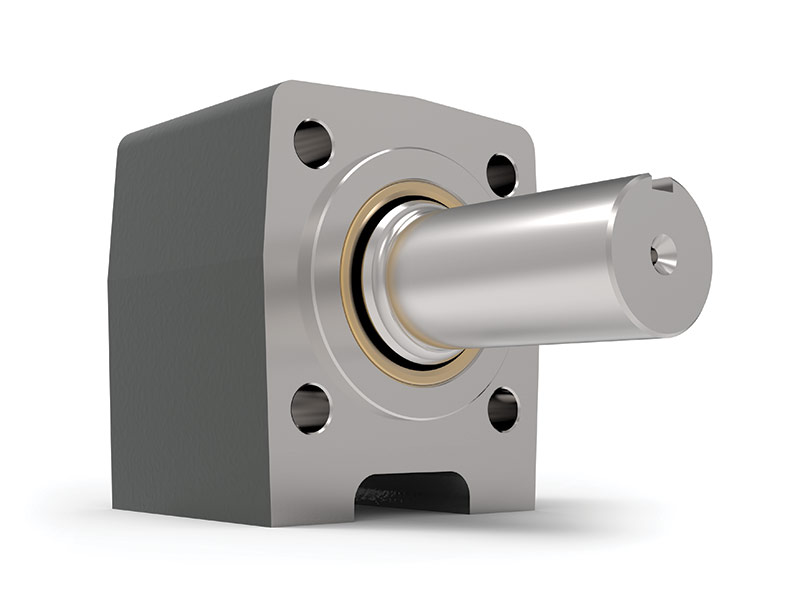

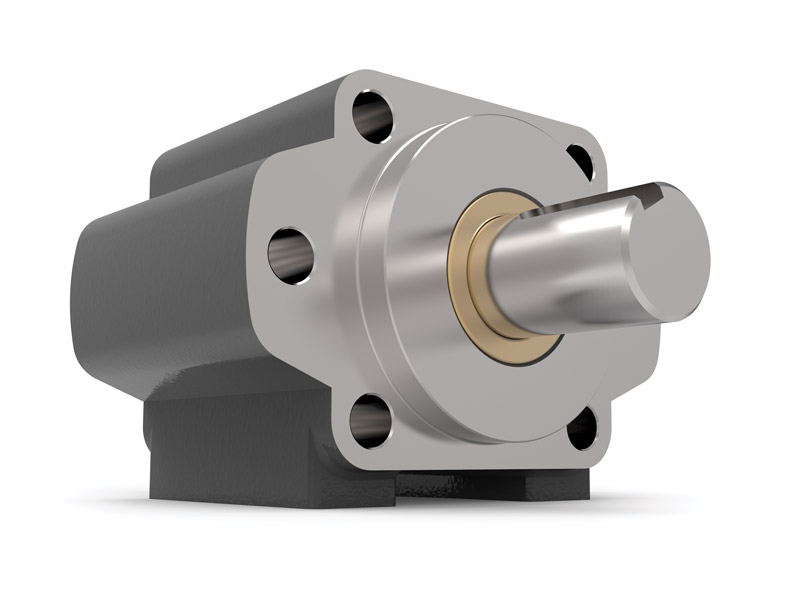

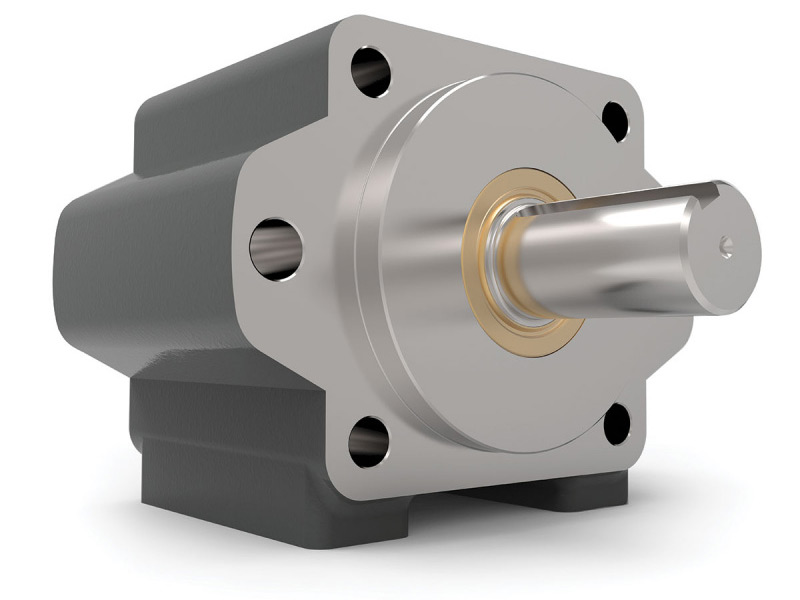

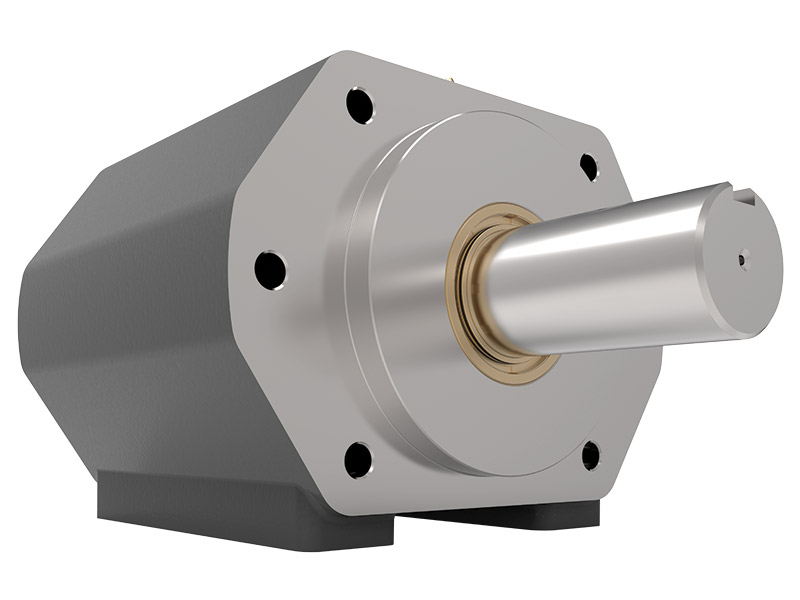

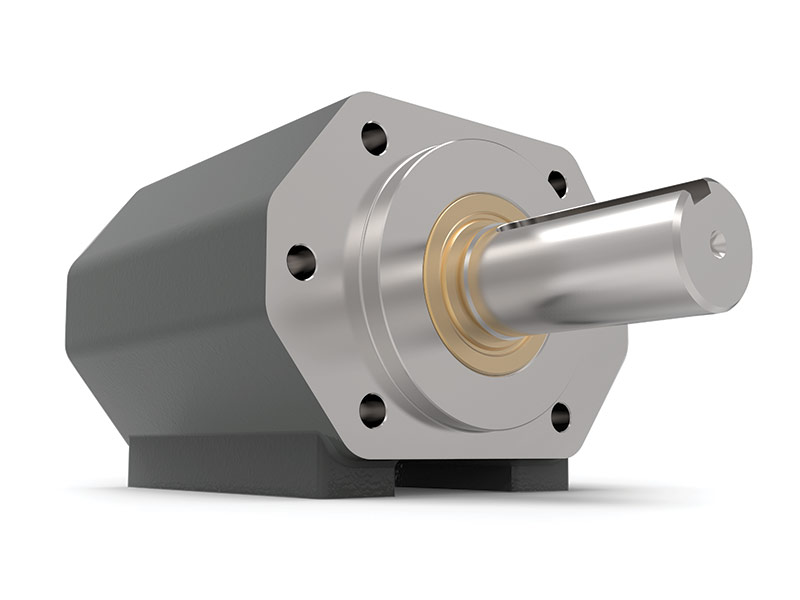

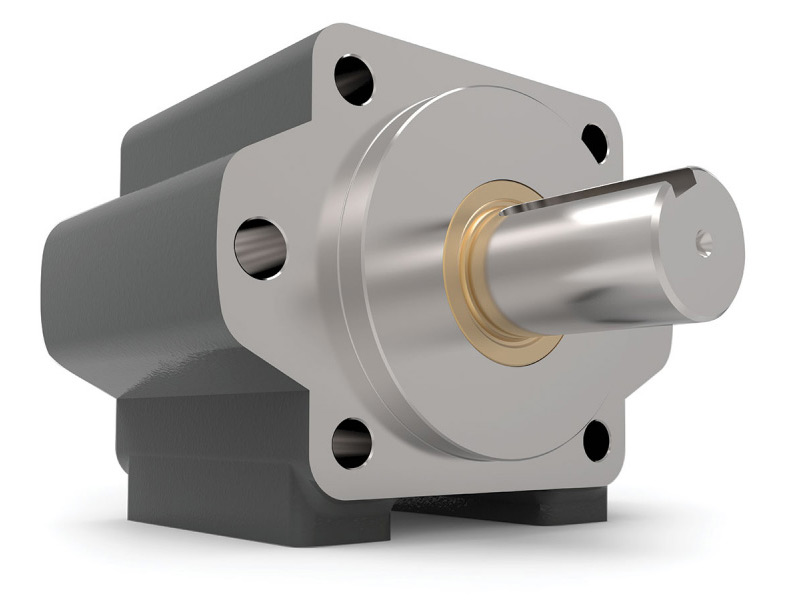

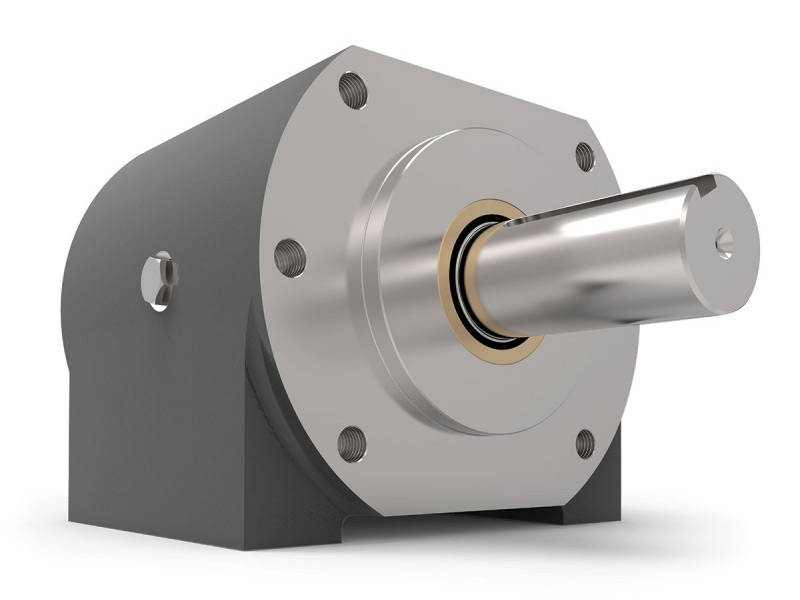

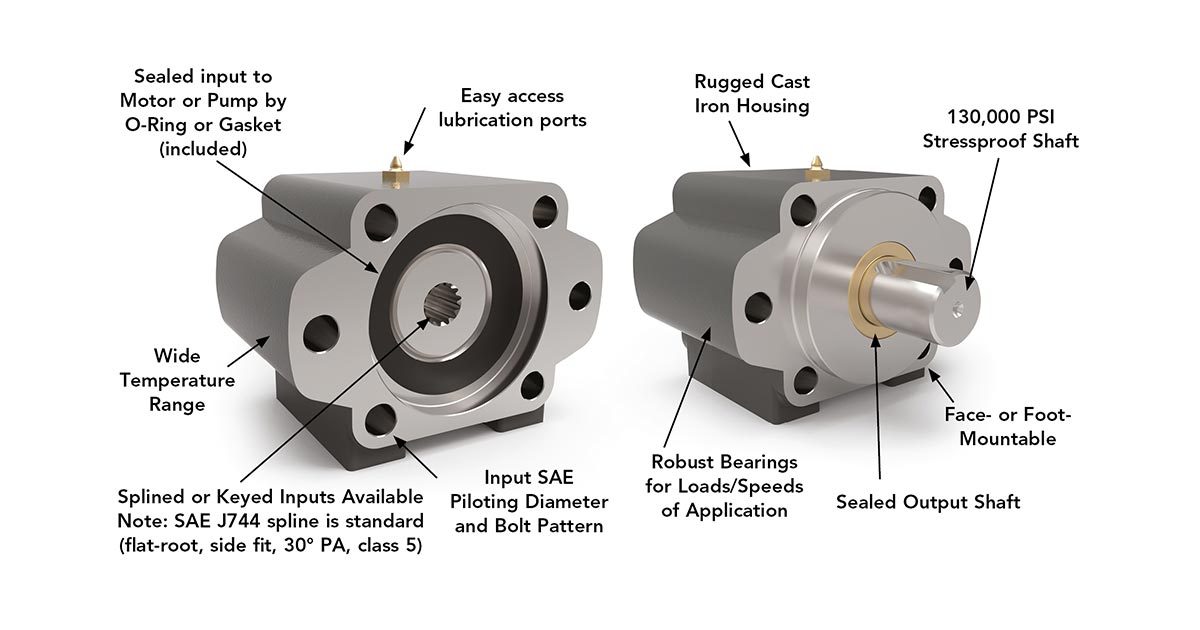

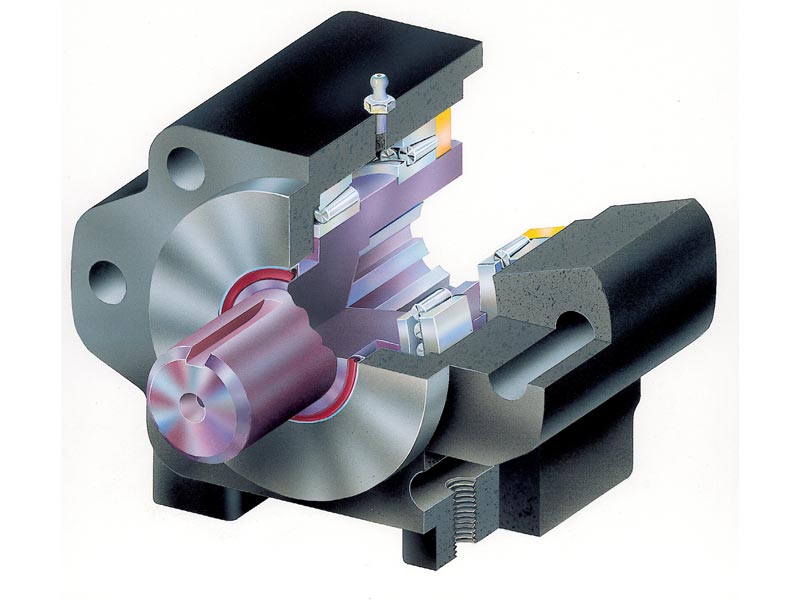

An overhung load adaptor is often referred to in German as an attachment bearing or outrigger bearing assembly, but this is only partially true. Consisting of a robust cast iron housing and an integrated bearing system, this bearing block system offers a variety of unique product features for smooth and long-lasting operation. The specific bearing arrangement and overall product design compensates for radial and axial load conditions and maximizes the service life of connected pumps and motors. A unique sealing system protects the hydraulic fluid from contamination and acts as a contamination barrier. Zero-Max overhung load adaptor are fitted with deep groove ball bearings as standard, spherical roller bearings are used for heavy duty applications.

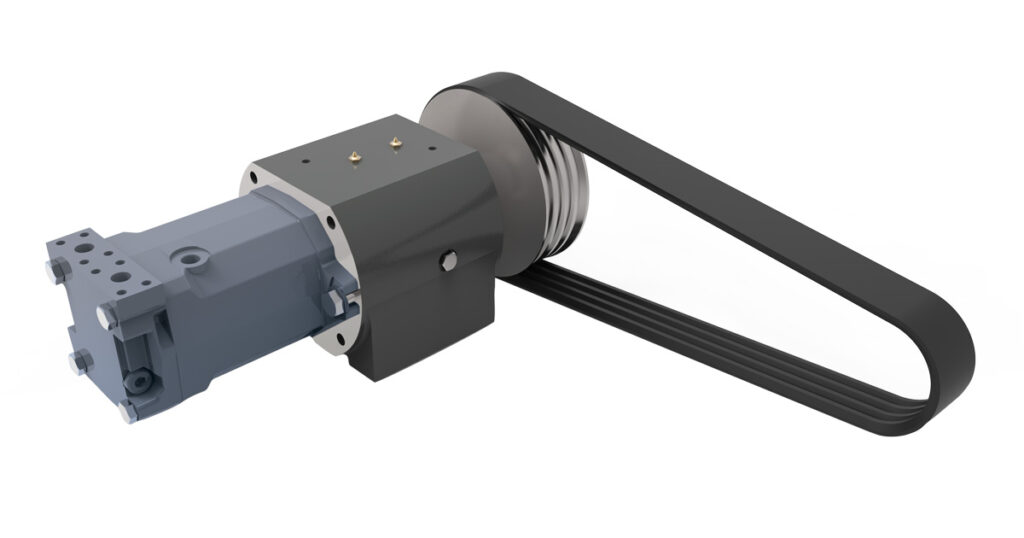

The Overhung Load Adaptors “OHLA” is used to prevent and avoid radial and axial loads in hydraulic systems. The use of radial load adapters increases the service life of hydraulic motors – and pumps in demanding applications. Overhung Load Adaptors, also known as outrigger bearings, prevent downtime and avoid costly damage to the system. The innovative sealing system with its integrated contamination barrier protects hydraulic fluid from dirt and contamination. Hydraulic motors can be removed for maintenance without damaging driven machine elements such as gears, pulleys or sprockets.

Typical applications include:

- Fan drives

- Recycling plant

- Mixing plants/agitators

- Industrial conveyor drives

- Hydraulic motor applications in the harshest conditions

- Use in belt/chain drives

What if my pump or motor does not fit the Zero-Max standard overhung load adpator?

In general, the standardized overhung load adpator are designed and dimensioned for hydraulic pumps and motor standards of the SAE (A-F) and non-SAE classification. For different mounting requirements, please contact us directly to ensure the required connection design. More than half of the overhung load adpator sold to date are individual and customer-specific designs.

What features does the overhung load adpator offer as standard?

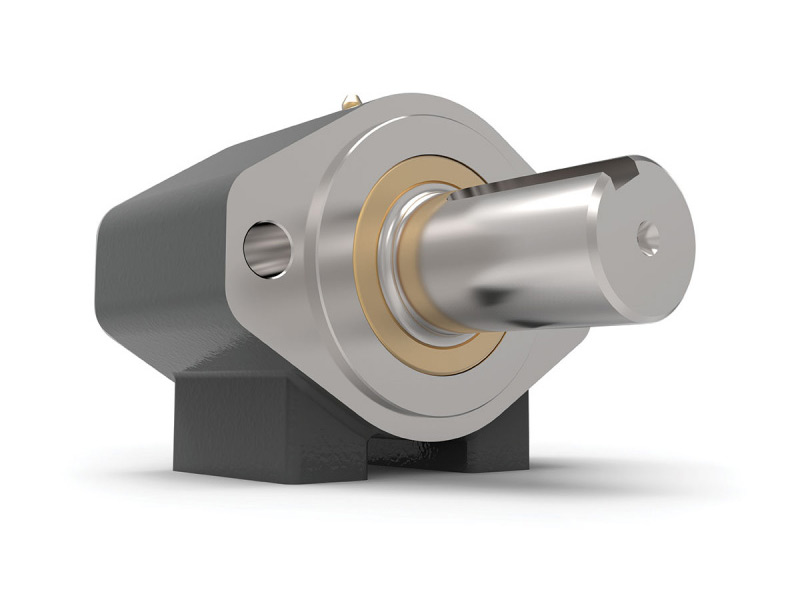

- Face and bottom mounting possible

- Protection against axial and radial loads

- Integrated contamination barrier offers protection against contamination

- Additional sealing option

- Steel shafts can be loaded up to 9000 bar

- Supports almost any drive and output configuration

- Can be used in horizontal and vertical applications

- Grease fittings and flow options

- Extensive customization options

What modifications or customizations can be implemented for overhung load adaptors?

The possibilities for individual customization are almost endless, with the most common modifications including:

- Adaptations to connection adapter solutions (DIN, ISO, IEC, NEMA, non-SAE) and corresponding upward and downward modifications

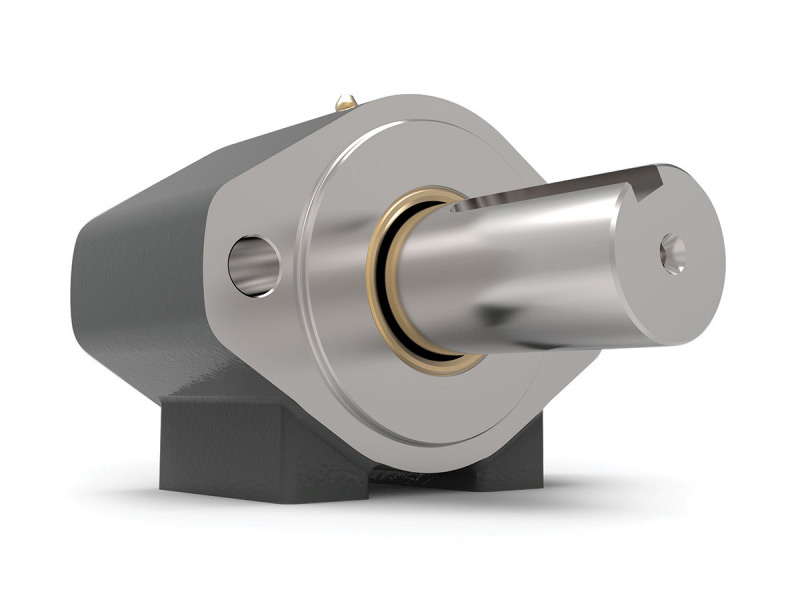

- Modified shaft designs (bores, splines, threads, tapers, etc.)

- Face seals

- Stainless steel shafts

- Surface-treated housings (nickel-plated, QPQ)

- Additional screw holes (sealing plugs, venting screws, threaded holes for mounting)

- Transition between two SAE installation standards

- Individual output shaft seals for harsh environmental conditions

What criteria need to be considered when using an overhung load adaptor?

Before using an overhung load adaptor, there are important considerations for determining the ideal product configuration. Reference products are often used to select a corresponding application to make an initial pre-selection. Performance or load specifications of reference products often refer to static key figures that do not consider essential factors that are required to determine the service life. Zero-Max offers an expected service life forecast based on a combination of dynamic load rating (service life estimate based on application details) and application-specific expertise. The load capacity of the drive mechanism should also be considered when selecting the overhung load adaptor. Together with its customers, Zero-Max develops individual overhung load adaptor solutions, adapted to the most difficult areas of use and fields of application.

The estimated service life can be determined by Zero-Max by specifying the following values:

- Power of the drive (HP or KW)

- Speed specification (rpm)

- Load type (fan, blower, pulley, sprocket, etc.)

Pulley = specification of the pulley diameter and the distance between the face and the pilot bore on the output side

Axial fan = fan weight and thrust force or load.

If the axial load is not known, it can be determined by specifying the fan diameter, the air flow rate (cfm or m3/h) and the static pressure.

- Installation position (vertical, horizontal, shaft direction upwards, vertical or downwards)

- Part number of the motor/pump or data sheet if applicable

In general, Zero-Max recommends providing the application specifications for L10 bearing life calculation and drive connection design. We will be pleased to check your application for further customization options, expected service life and possible performance improvements.

Why is Zero-Max recommended as a provider?

Zero-Max has been a recognized manufacturer and developer of overhung load adaptors for decades and a reliable supplier of drive technology solutions for more than 70 years. Our unique experience combined with our expertise in demanding applications enables us to offer customized solutions.

- Evaluation of wear/input torques

- Assessing and designing the estimated service life

- Application-specific lubrication recommendations

- General application-specific recommendations (e.g. vertical, high-speed fans, etc.)

- Technical support

- Internal quality control and verification

- Standard designs are available from stock

- Customized solutions are developed in-house

- Certification according to ISO 9001:2015

In which industries and areas of application are overhung load adaptors used?

In general, overhung load adaptors are the ideal solution for mobile hydraulic applications. Zero-Max offers a wide range of optimum product solutions, particularly for areas of application with enormous requirements due to environmental conditions, high axial and radial loads and other critical factors.

(woodchippers, wood mulchers, wood shredders, shredders, mobile sawmills, stump grinders, pallet conveyor systems and much more)

(Seed drill blowers, harvesting machines, lawn mowers, liquid manure injection equipment, liquid manure fertilizer pumps, fertilizer spreaders, PTO drives)

- Mining

(rock crushers, oil extraction – fracking, heat exchangers, submersible sewage pumps)

(road sweepers, water cannons, gravel removal, grading machines, road milling machines, road surface blasting, concrete mixers)

- Marine

(seawater cooling units, bow thrusters above deck, vertical cooling fans, propeller attachments, weed removal, winch drives)

(General mobile hydraulics, cooling towers, food technology)

- Other applications

(design as adapter solution, car wash systems, underwater applications, pump drives with belts)

What are the recommended lubrication methods?

The preferred method of lubrication for most Zero-Max overhung load adaptors is grease lubrication. For a wide range of applications, grease offers optimum characteristics such as low maintenance, few problems with leakage and a reasonable service life. Specific requirements and/or personal preferences necessitate the use of static oil or continuous oil lubrication. For modifications regarding individual lubrication options, please contact Zero-Max. Gear teeth and splines should generally be lubricated during installation. The recommended quantity and type of grease can be found in the OHLA lubrication and operating recommendations.

Indoor

Lithium Basis NLGI #1 or NLGI #2

Outdoor

Lithium Basis NLGI #1 or NLGI #2 (Synthetic recommended)

Severe/Food Grade

Consult Zero-Max to determine if special grease ist needed.

It is important to adhere to the specified characteristic values and information to prevent problems later. Compliance with the specifications is a prerequisite for achieving the expected service life.

What does it mean if the overhung load adaptor “runs hot”?

It is normal for the overhung load adaptor to heat up during operation and this is usually not detrimental to its functionality. Factors influencing the warming of the assembly include the operating speed, load, type of lubrication and environmental temperature. Running without load can also lead to excessive heat generating. In suspected cases, the operating temperature can be checked using a temperature sensor or infrared thermometer. Zero-Max overhung load adaptor in the standard version are designed for the temperature range from -40°C to 100°C. In cases of deviation, please contact Zero-Max directly.

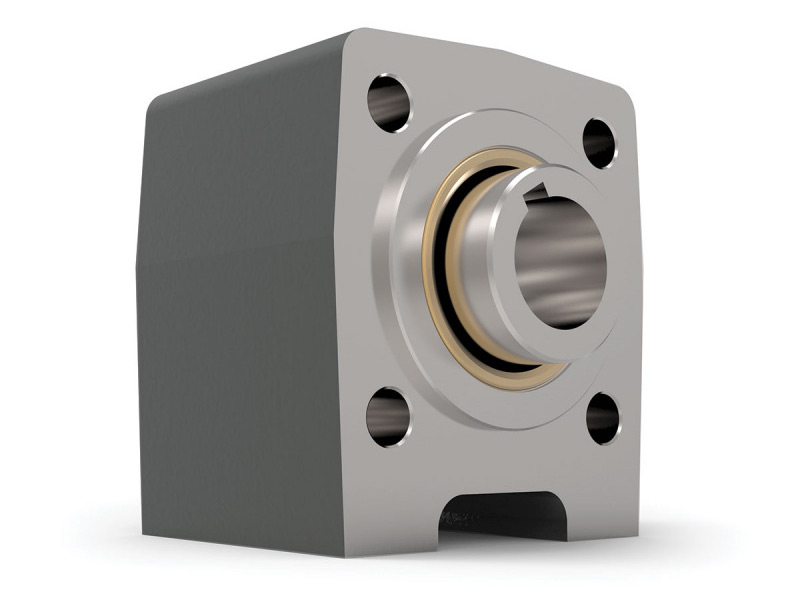

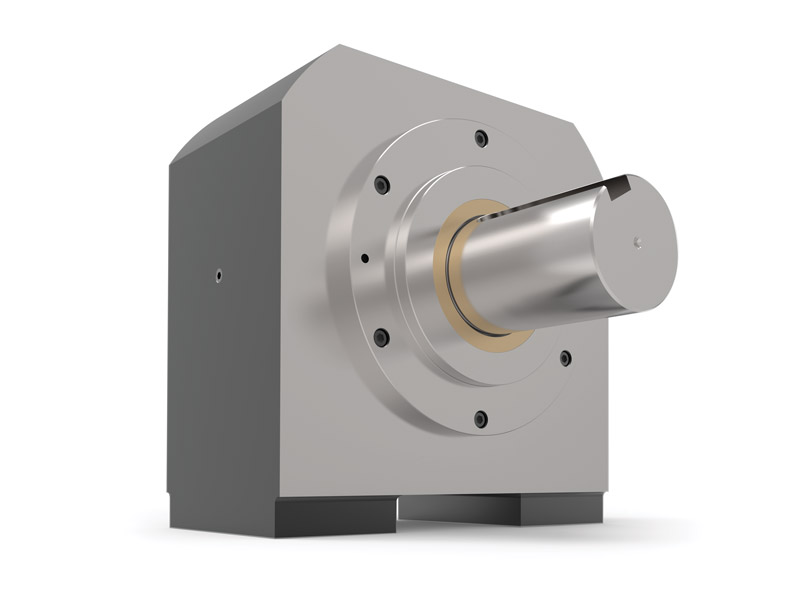

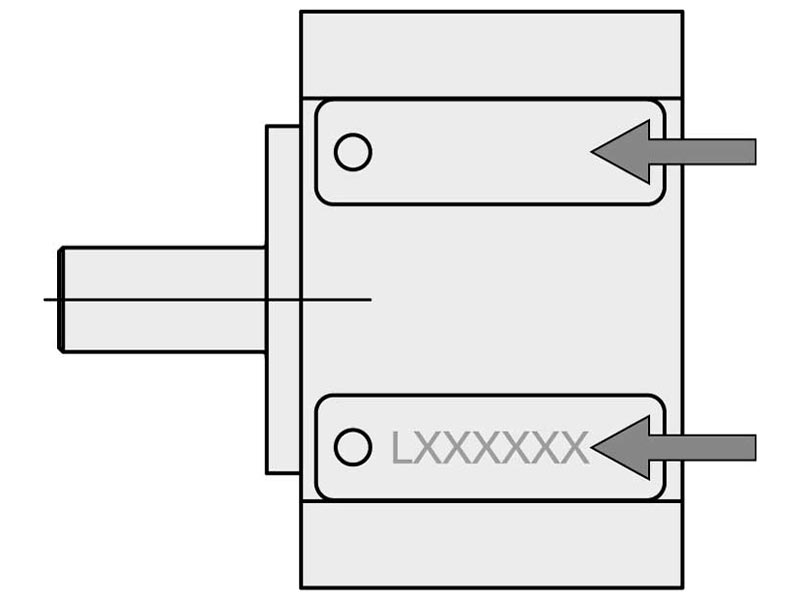

How do I identify an overhung load adaptor (OHLA) for replacement?

In the case of customized or individual overhung load adaptor, a special part number on the base or bottom side can be used to identify the unit. Corresponding part numbers begin with an “L” and six digits. (see figure X)

If no part number is stamped on the bottom, it is a standard overhung load adaptor. A comparison of the housing and shaft dimensions with the catalog data makes it possible to determine the series and available version.

What is the difference between the overhung load adapter (OHLA) and conventional bearing systems?

Classic outrigger bearings can compensate moderate axial and radial loads on the shaft connection. Often, outrigger bearings are designed for standardized gear pumps of groups 1, 2 and 3 and are often intended for drives using V-belts or chains. In contrast to outrigger bearings, overhung load adaptors offer unique and innovative product features to increase the service life of motors and pumps. Depending on the area of application and load case, a distinction is made between further benefits that overhung load adaptors can offer.

- A durable cast housing combined with robust and long-lasting bearing combinations enable long operating times, even under the most difficult environmental conditions.

- Extended housings, for example, offer significantly improved load support to the bearings, maximizing load capacity and service life.

- Requirements for high-speed operating conditions can be considered through the optional use of spherical roller bearings.

- Heat-treated shafts with drive bore splines allow higher torques and result in better shock load characteristics.

- The innovative and unique sealing system enables protection against contamination and serves as a contamination barrier.

- In particular, the customer-specific adaptation and modification options for specific application areas and load conditions is an enormous product advantage compared to classic front-end bearings with standardized product properties.

- The possibility of front and base mounting has proven to be advantageous, whereas most attachment bearings only offer a single-sided mounting option.

- A wide range of possible standard drive bore sizes from ø15.875 mm to 88.9 mm enable use in almost all industries.

- The use overhung load adaptors allows hydraulic motors to be replaced for maintenance purposes without damaging driven gears, pulleys or sprockets.

Do you have questions about the product? Contact us and we will be happy to advise you personally.