In modern machines and drive systems, power density and process speeds are constantly increasing. At the same time, the demands on protective mechanisms that shield expensive machine components from overload, blockage, or incorrect operation are also increasing.

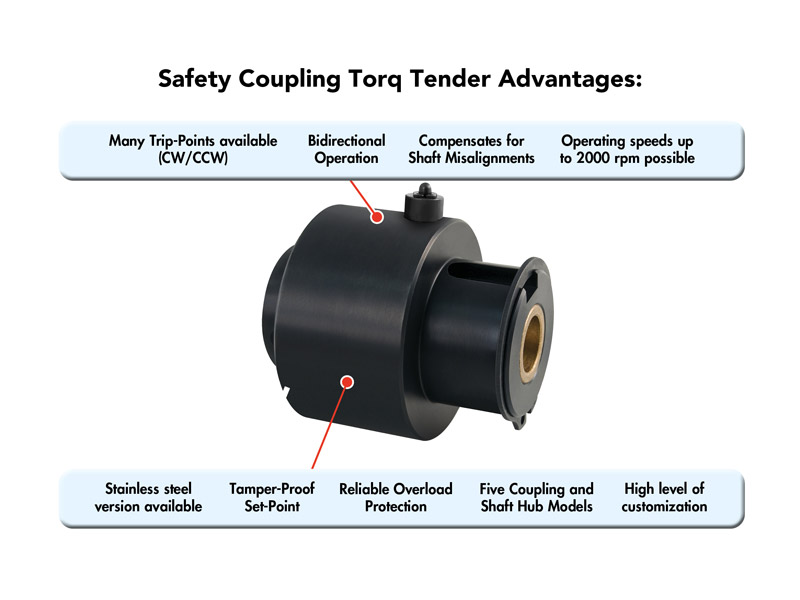

The Zero-Max Torque Tender was developed precisely for this purpose: as a compact, low-maintenance, and high-precision torque limiting system—reliable, repeatable, and ready for immediate use.

What is a Zero-Max Torque Tender?

A torque tender is a mechanical overload protection device that engages or disconnects when a defined torque is reached in order to protect downstream components.

It acts as a “safety coupling” – but with a unique operating principle that allows extremely precise force limitation without complex settings or constant readjustment.

What is the difference between the Torque-Tender and conventional safety couplings?

- Classic Safety Coupling (Ball-Detend Principe)

Classic safety couplings often work using the “ball detent principle,” i.e., when a defined disengagement torque is exceeded, the balls are pushed out of their defined position.

- How the Zero-Max Torque-Tender works

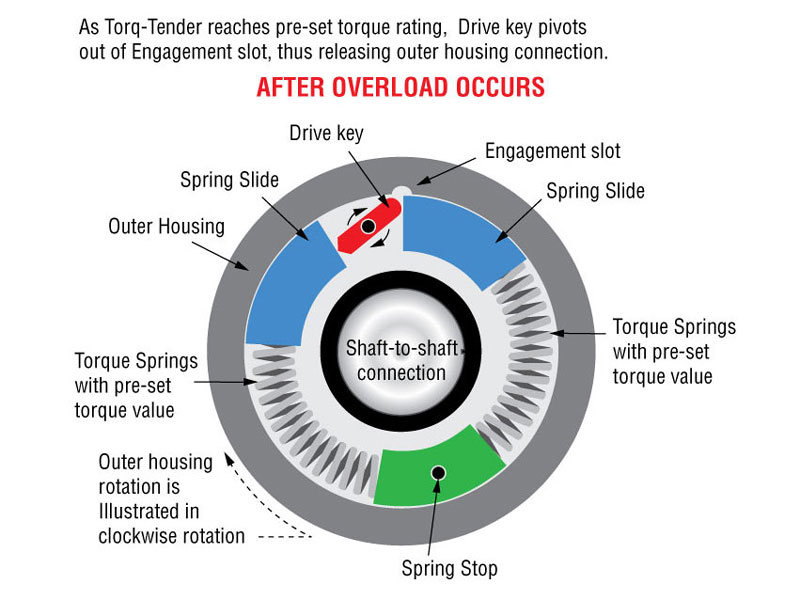

The spiral springs used define the release torque of the Torque-Tender and thus differ in their mode of operation from safety couplings with a ball- detent principle. In the event of overload, the positioning pin is pushed out of its rest position on the outer housing, thereby disconnecting the connection.

What makes the Zero-Max Torque Tender unique?

Various disengagement options available

- Different disengagement torques possible in both directions of rotation (CW/CCW)

(e.g., clockwise 5 Nm and ounterclockwise 8 Nm) - Free wheel option

- Unilateral and/or bilateral blockage behavior

High degree of individual customization

- Special sealing technology

- Customization to specific components (gears, pulleys, etc.)

- Custom coatings

- Specific material selection

Extremely precise torque limitation

- Reproducible and reliable disengagement torques

- Ideal for applications where an exact limit is crucial

- Protection against overload, crash, blockage, or operating errors

Self-reset after overload

- After reducing the load (torque reduction), the Torque Tender automatically returns to its original position

- No manual reset required

- Maximum process availability – no downtime for reset procedures

Robust, compact, and low maintenance

- Very simple, robust mechanics (optimized for installation space)

- Practically wear-free – no components requiring frequent adjustment

- Works reliably even under dirty conditions and when exposed to temperature and vibration influences

Plug-and-play integration

- Configured ex works with defined disengagement torque

- Easy to integrate into existing and new drive systems

- No special knowledge or complex settings required

In which areas of application is the Torque-Tender primarily used?

- Packaging machines

- Pharmaceutical and medical technology

- Conveyor technology and material handling

- Food and beverage industry

- Mechanical engineering

- General automation

- Special machine construction

- Printing and converting machines

- Manual operation (e.g., handwheel operation)