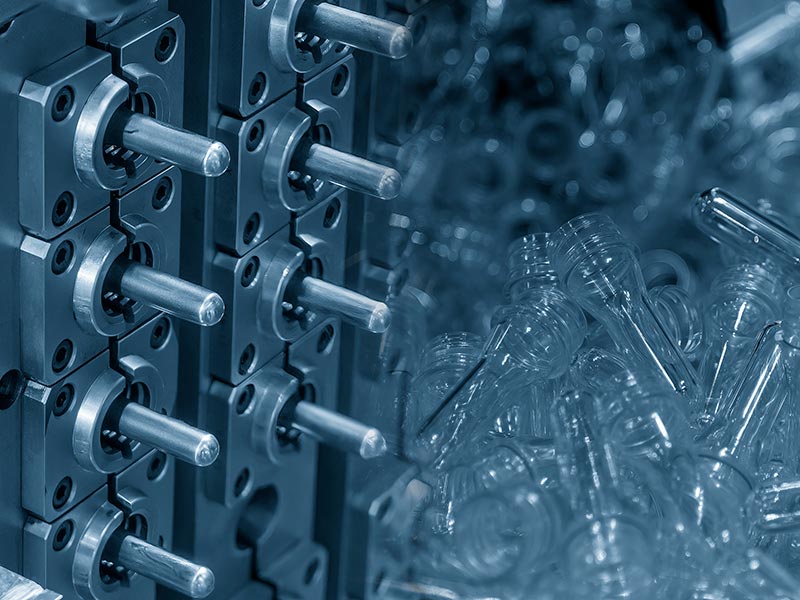

CD Couplings for Bottle & Can Manufacturing and Filling

High volume bottle and can manufacturing requires precise, repeatable and accurate equipment to meet industry demands and ensure smooth, consistent, high-volume production. Zero-Max is a premier supplier of custom and standard Composite Disc (CD®) Couplings and additional motion control components designed to meet the most demanding production cycles. Our components can fit to your existing systems with the turn of a screw to reduce changeout downtime and improve accuracy. Whether you specialize in can manufacturing, printing, stamping, bottle forming, filling, or anything in-between, we have solutions for your manufacturing processes.

CD Couplings for 2-Piece & 3-Piece Can Manufacturing

Flexible Shaft Couplings for Can Manufacturing often require zero-backlash and high torsional stiffness, and are subjected to repetitive reversing, stopping, indexing, and high cycle rates. Zero-Max Composite Disc Couplings, including Single-Flex, Double-Flex and Floating Shaft couplings, hold up to these punishing conditions while also providing vibration-damping. Our CD Couplings are field proven in various can printing applications, including rotating large diameter carousels with multiple printing cylinders.

CD Coupling Features:

- Zero Backlash Operation

- Exceptional Performance and Precision

- Perfect for High-Speed Applications

- High Torsional Stiffness

- High Misalignment Capacity / Low Reaction Loads

- Ideal for Reversing and Indexing Operations

- Maintenance-Free Operation

- Long Operational Life

Zero-Max is the industry leader in Composite Disc Coupling technology. View our CD Couplings or contact us for a comprehensive overview of all product specifications.