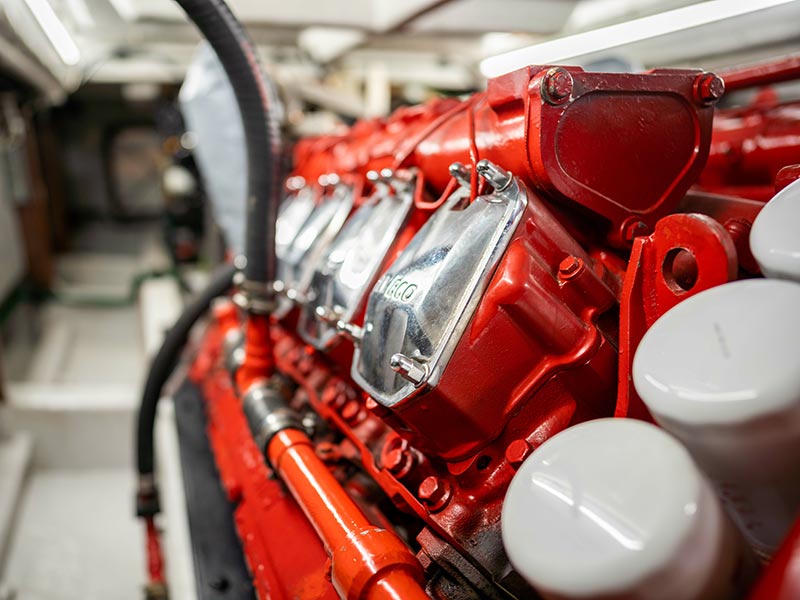

Maritime Applications

Durability, resistance to corrosion and longevity are usually the first terms associated with requirement profiles for maritime applications. Equipment components and machine parts in particular are exposed to extreme conditions. In applications such as propeller connections or refrigeration units, long-term heavy loads on the mechanical components can lead to damage or malfunctions in hydraulic motors or pumps. To avoid downtimes and additional repair costs, it must be ensured that the components used guarantee a smooth process.

Extended life due to avoidance of breakdowns

Zero-Max Overhung Load Adaptors protect hydraulic motors and pumps from radial and axial loads and thus prevent malfunctions. The overhung load adaptors absorb the loads that occur and have been proven to extend the service life of pumps and motors.

With an innovative integrated sealing system, overhung load adaptors protect the system from contamination, dust, water and other dirt contaminants. Overhung load adaptors (OHLA) act as a contamination barrier and protect critical hydraulic and fluid systems from contamination. Individual customization to meet specific requirements often enables unique features such as noise and vibration reduction.

A common requirement profile for applications in the maritime sector is to enable stability in heavy seas and harsh weather conditions. This enables requirements regarding shock loads such as 3G (vertical) and 2G (axial/longitudinal) for highly demanding 360° rollover requirements. A limitation of the engine power is ensured even under high dynamic roll and pitch angles.

Constant and unexpected loads make it necessary to consider protection against wear and fatigue caused by permanent stress. The compact and robust design of the OHLA, combined with simple installation on standardized mounting surfaces, offers real added value for a wide range of applications.

Possible use case of an overhung load adaptor:

Typically, maritime applications often involve heavy loads in terms of axial and radial load profiles. An installed shaft coupling often serves as a compensating element to equalize the loads that occur. Depending on the application, it is possible that radial loads cannot be fully compensated by a shaft coupling, taking possible misalignments into account. An appropriate bearing selection for the Overhung Load Adaptor can be made considering known influencing factors such as radial load, misalignment possibility of the coupling, etc. A final evaluation and service life calculation enables a significant increase in the service life of other connected components.

The Overhung Load Adaptor can also act as a contamination barrier, for example in bow thrusters the hydraulic motor is effectively protected in the water and copes with the thrust forces of the propeller, which also protects the bearings in the hydraulic motor.

Extensive design options and standard SAE mounting options

Overhung Load Adaptors (OHLA) from Zero-Max were developed with the aspect of versatile application possibilities and compatibility with maritime applications in mind. Zero-Max manufactures OHLAs in the SAE (A-F) mounting standards as standard. Zero-Max has decades of expertise in customized mounting options and other application-specific requirements to ensure compatibility with engines, gearboxes and other components. To simplify installation, all models offer a face and foot mounting option.

Overhung Load Adaptor (OHLA) are used in maritime applications:

- Refrigeration units

- PTO adapter

- Propeller

- Weed harvester

- Bow thruster

- Winch drives

- Belt-driven hydraulic pumps

- Generators and alternators

- Dredging systems (drive augers for sand and sludge removal)

Modifications and customized solutions

Maritime applications are often unique and differ from specific requirements. Specifications resulting from the requirements allow the use of standard Overhung Load Adaptors or make customized solutions necessary. Zero-Max offers the necessary know-how to design customized solutions, adapted to the customer’s requirements. The implementation of all relevant processes in the in-house team enables customer-specific solutions, regardless of the quantity.

Technical Support

The Zero-Max development team ensures that application requirements are met at every stage of the project. Our developers have in-depth knowledge of maritime applications and design solutions for use in harsh environmental conditions. Zero-Max products are designed for a long service life and maximum performance and have been proving their efficiency in use under extreme conditions for decades.

Have we sparked your interest? Then we look forward to hearing from you.