Servoflex Disc Pack Couplings

Torsional stiffness and low inertia

Why are there different names for the servo multi-disc coupling with Servoflex and ServoClass?

In general, the Servoflex coupling and the ServoClass coupling are identical in design and function. The ServoClass coupling is sold exclusively in the USA under this name. The Servoflex coupling, on the other hand, was originally developed and introduced to the market by our parent company Miki Pulley Co. Depending on the place of distribution or use, both versions may be installed or used.

Which product features of the backlash-free servo multi-disc coupling Servoflex or ServoClass are particularly advantageous?

- High torsional stiffness for precise positioning

- Low inertia for high-speed applications (good concentricity properties)

- Economical servo motor coupling adapted to RoHS guidelines without the use of prohibited substances

- Backlash-free operation and low hysteresis properties enable precise and repeatable positioning

- Availability for clean room applications (ISO class 6)

Which features of the Servoflex coupling are particularly noteworthy?

Mass inertia and torsional stiffness:

Torsional stiffness and mass inertia are decisive characteristics for high-quality servo motor couplings. A low mass inertia of the coupling is essential to keep the overall inertia of the servo system low. The lower the moment of inertia, the less energy is required to set the system in motion. Taking this into account can result in higher possible accelerations. The torsional stiffness of a coupling should be correspondingly high to prevent torsion wind-up due to acceleration, deceleration or reversing sequences. The standard torsional stiffness of the Servoflex shaft coupling results in a higher system resonance frequency, which in most cases is well above the permissible operating range.

Backlash-free:

Another important component of a high-performance servomotor coupling is absolute zero backlash. Shaft couplings are often described as backlash-free but still have a high level of possible torsional torque (winding). Backlash-free coupling means the ability to ensure the same relative relationship between the input and output shafts without tolerating any loss of movement or position. A high torsional torque can have a negative effect on the servo system. The use of a shaft coupling with an increased torsional moment (rewinding) causes positioning errors. The backlash-free Servoflex shaft coupling ensures a very low torsional torque due to its innovative product design.

Misalignment capacity / compensation of misalignment:

Another critical factor for servo motion control systems is the ability to compensate for shaft misalignment or out-of-alignment. Servo applications tend to gradually degrade from their original alignment condition over time and under high application loads. A coupling should be able to compensate for or tolerate this. Other properties are often required of a coupling; possible concentricity errors of connected shafts and the combination of other component or assembly tolerances should also be considered. High misalignment capacity is particularly important to best compensate for the transmission of reaction loads to bearings and bushings in the overall system. The Servoflex coupling enables a high level of flexibility without having to compromise on torque capacity or torsional stiffness, thus minimizing possible reaction loads on the bearings of the servomotor.

In which case is a single-cardanic (Single-Flex) or a double-cardanic (Double-Flex) ServoClass or ServoFlex coupling recommended?

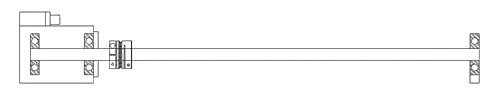

In many applications, the double-cardanic Double-Flex is preferred due to its higher misalignment capacity (offset compensation), whereby a bearing system based on four bearings is typically ideal.

For bearing arrangements with four bearing locations, the shafts are fully supported, but in most cases exhibit unavoidable misalignments or develop over the period of use. The use of the double-cardanic Double-Flex coupling offers the possibility of compensating for parallel, axial and angular misalignments. Reaction loads on connected parts and components can be kept to a minimum.

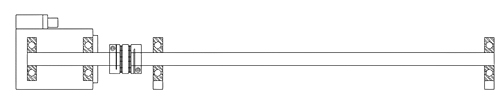

The single cardanic Single-Flex coupling is ideal for shaft connection applications. Typical applications are “semi-floating” shaft connections with three bearing points as shown below:

The single-cardanic Single-Flex coupling cannot compensate for parallel shaft misalignments, but it can be used in structurally limited installation spaces with ideally mounted shafts in order to avoid parallel misalignments. Possible application examples include the use of two Single-Flex couplings at both shaft ends to create a floating shaft coupling connection and thus enable a greater DBSE (Distance Between Shaft Ends).

Can I choose a keyway in the bore of the hub?

The ServoClass or Servoflex coupling is designed without a keyway; optional integration of a keyway according to customer requirements is possible. In many cases, Zero-Max can also offer customized keyway sizes. As standard, the keyways are offered in DIN standard 6885 for metric shafts in g6-h6 and h7. Of course, we also offer keyway designs according to ANSI / AGMA 9002 standard.

Is it possible to get customized or individual bores or keyways?

Zero-Max offers a variety of possible bore and keyway sizes, including metric bore sizes in whole millimeter increments and inch bores in 1/16-inch increments. Of course, Zero-Max also enables customer-specific bore sizes and non-standard keyways. It is also possible to obtain individual bore tolerances and keyways to meet specific dimensional requirements.

What is the maximum operating torque for the Servoflex coupling?

The rated operating torque specified for the ServoClass coupling is the maximum permissible torque for the coupling. All peak torques or torque peaks expected in the application should be taken into account when designing for the specified operating torque.

How much should the minimum engagement of the shaft in a Servoflex coupling hub be?

Ideally, the minimum engagement should cover the entire length of the hub (dimension “LB” in the catalog). The shaft may also extend beyond the end of the hub into the area of the disc pack. The disc pack (dimension “K” for the disc diameter) or the shaft or hub on the opposite side should never come into contact with the shaft. If the shaft cannot cover the entire length of the hub, it must be ensured that the entire bending range of the hub is taken into account in order to transmit the full torque range. This range is approx. 2/3 to ¾ of the total hub width, depending on the coupling size. If you have any questions, please contact Zero-Max directly.

Is it possible to mount a hub without a keyway on a shaft with a keyway or a flattened shaft?

The coupling hubs of the Servoflex coupling can be mounted on shafts with an “open” keyway or flattened shafts. The transmittable torque can be slightly reduced due to the smaller clamping surface caused by the open keyway connection. This is not normally a problem, but should be considered, especially with smaller bore sizes. Please contact Zero-Max directly if you have any further questions.

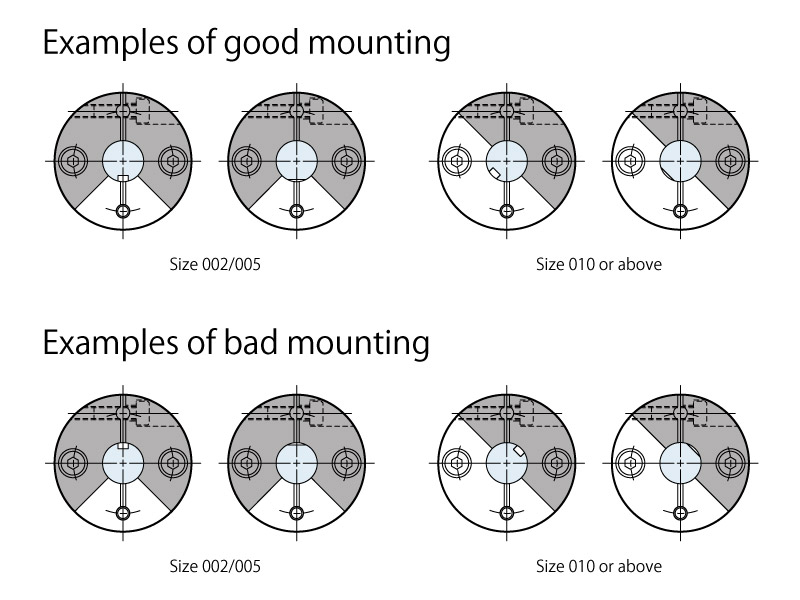

To achieve the optimum clamping force, we recommend positioning the keyway or the flattened surface opposite the clamping screw connection. Below you will find the corresponding diagram for the optimum position of the keyway:

Can I connect tapered shafts in my application using Servoflex couplings?

Zero-Max offers tapered adapters for a wide range of sizes. The clamping hub itself offers no possibility of clamping on the cone. The conical bore adapter ensures secure and homogeneous clamping of the standard clamping hub bore on the conical shaft via the integrated inner cone. The taper adapters have an internal taper of 1:10 and are therefore suitable for Fanuc servo motor shafts or comparable designs. The available taper adapters have a main taper diameter of 11 mm, 14 mm and 16 mm.

Is it possible to replace the disc elements on site?

It is not possible to change the disc packs on site. Zero-Max has specially developed assembly stations and tools for this process. This enables us to assemble the shaft couplings with the required concentricity and ensure that optimum performance and service life are guaranteed.

Can Servoflex couplings be dynamically balanced?

Zero-Max Servoflex couplings can be dynamically balanced depending on the application. Typically, applications with high operating speeds or vibration-sensitive systems can benefit from dynamically balanced couplings. Zero-Max has the necessary technology to meet the relevant requirements, meaning that the majority of requirement profiles can be implemented “in-house”. This option enables us to offer an economical solution with a fast turnaround time.

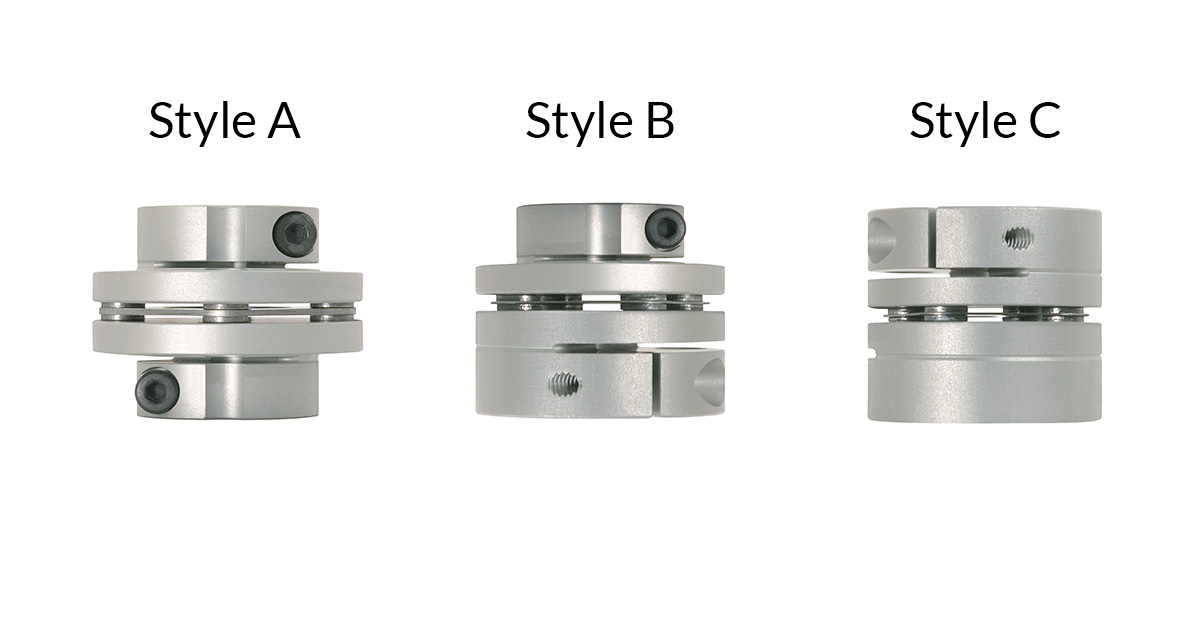

Is it possible to choose between the different designs of the Servoflex coupling (“A”, “B” and “C”)?

It is not possible to choose between the different designs. The specified hub combination results from the coupling size and the required bore size. Some sizes offer a reduced hub diameter for smaller bore diameters, which provides a higher clamping force while ensuring optimum performance. Coupling sizes with reduced hub diameters are shown in the catalog with the corresponding bore ranges. For bores with larger bore diameters than listed in the reduced hub diameter section of the catalog, the standard diameter is used.

- Design “A” has (2) hubs with reduced diameter

- Type “B” has (1) hub with reduced diameter and (1) hub with standard diameter

- Design “C” has (2) hubs with standard diameter

Why should you choose a Servoflex coupling instead of a CD coupling, or vice versa?

In most cases, the size of the coupling required for the application will determine whether a Servoflex coupling or a CD coupling is used. In general, the Servoflex coupling size range is suitable for smaller applications in terms of torque, load and shaft size. The CD coupling size range, on the other hand, is more suitable for larger applications. There are some coupling sizes of the Composite Disc Coupling and the Servoflex Coupling that overlap. In these cases, it depends on the application and requirements such as misalignment, torque, torsional stiffness, vibration, shock load capacity, lead time, cost and more as to which product is more suitable. Contact Zero-Max to discuss your specific requirements.

Which areas of application are ideal for Servoflex couplings?

- Robotics

- Machine tools

- Packaging machines

- Printing machines

- Automation systems

- Applications with ball screw

- Servo motors

- Linear actuators

- Precision gearboxes

Which customer-specific modifications could be implemented?

- Additional disc elements to increase the torque and torsional stiffness

- Customized keyway designs

- Integration of spacers for longer DBSE (Distance Between Shaft Ends)

- Taper adapter for tapered shaft connections

- Customized surface finish

- Customized bores, splines

- Versions in various materials (e.g. stainless steel)

- Product implementation as line-shaft or distance coupling design

- Customized hub designs according to customer requirements

- and much more

What advantages does a Servoflex multi-disc coupling offer compared to classic jaw & spider coupling?

In general, servo multi-disc couplings offer greater torsional stiffness than claw couplings, which often goes hand in hand with higher operating speeds and greater precision. Servoflex couplings offer comparatively low reaction loads. Why are low reaction forces so important? The resulting bearing loads often lead to reduced service life and noise. Servoflex couplings are less “susceptible to fatigue”, whereas spiders in jaw couplings change over time due to thermal influences (heat), which can lead to a drop in performance.