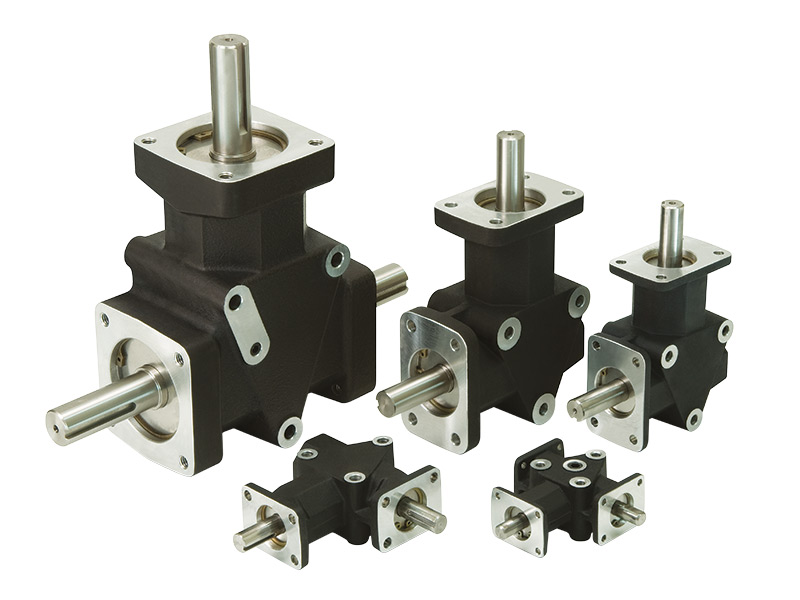

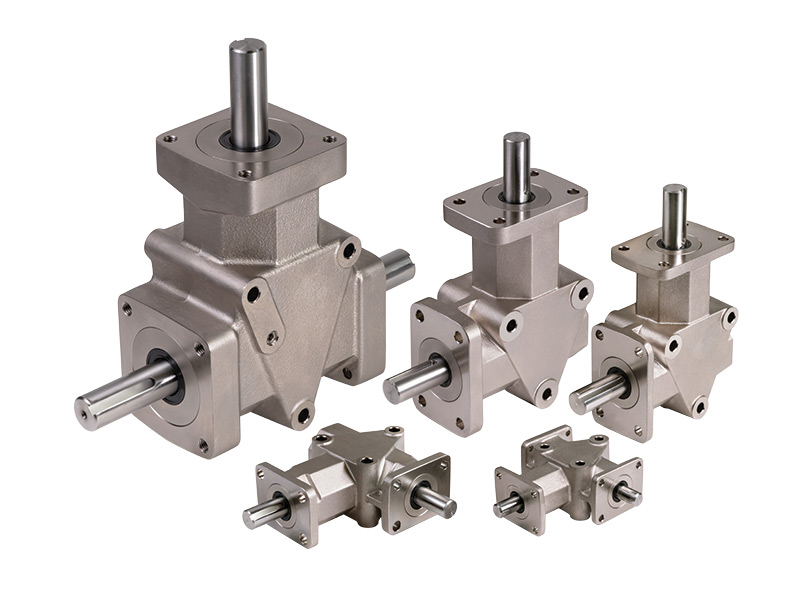

Two-way and three-way right-angle gearboxes

Quiet and compact

The use of high-quality spiral bevel gears with curved tooth flanks improves the contact between the gears and enables a higher torque with low running noise and vibrations.

The closed design with bearing-mounted shafts offers smooth and quiet operation and ensures that the internal gearing is not misaligned or contaminated by deposits.

Counter-rotating right-angle gearboxes are equipped with two output shafts as standard, which rotate simultaneously in opposite directions and thus create an ideal balancing ratio. Counter-rotating 90-degree right-angle gearboxes can be used for applications that require additional stability in mechanical drive systems or to compensate for vibrations.

What are the most common customized modifications that have been implemented?

Zero-Max right-angle gearboxes can be customized and individually adapted to the relevant operating conditions. Frequent adaptations are:

- Customized shafts (length, gearing, thread, bores, etc.)

- Housing modifications (installation dimensions, etc.)

- Specific lubricants

- Reduced backlash

How much backlash is present in a Crown angular gearbox?

As standard, Crown angle gearboxes have a backlash of approx. 0.5°. For customized versions, we can reduce the backlash to a value of 0.25°.

What characterizes Zero-Max right-angle gearboxes?

A robust product design combined with precision-manufactured individual components promises long and maintenance-free operating characteristics. Full control of product characteristics through internal machining, processing, and testing. 2-way and 3-way versions with transmission ratios of 1:1 and 2:1 are available as standard.

How high is the efficiency of a Crown right-angle gearbox?

An efficiency of approx. 96% is achieved by using high-quality spiral bevel gears and ball bearings.

Can I reverse the direction of rotation between the input and output shafts of the Crown right-angle gearbox?

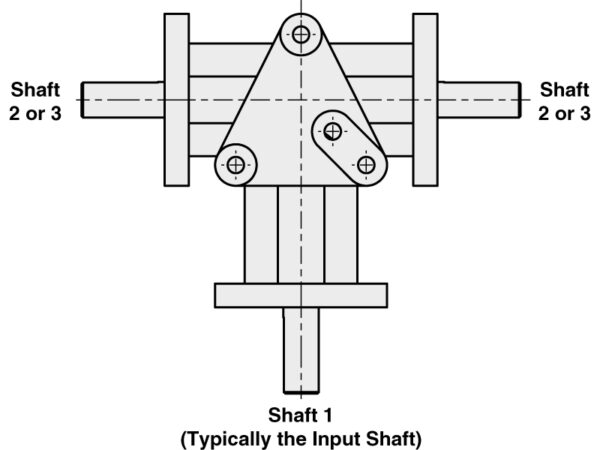

For the 2-way version (L version), the corresponding direction of rotation can be designed as specified in the catalogue. In selected cases, right-angle gearbox designs in opposite directions of rotation can be offered individually. For this purpose, 3-way right-angle gearboxes (T-design) are used as a basis and the corresponding third shaft output is shut down or removed (in the factory or on site).

In the 3-way version, the shaft ends for shaft 2 and shaft 3 are symmetrical to shaft 1. By turning the complete right-angle gearbox along shaft 1, the direction of rotation changes accordingly on shafts 2 and 3 in the same mounting position.

Does the Crown right-angle gearbox need to be lubricated?

All Crown right-angle gearboxes are lubricated at the factory and do not need to be lubricated at the time of installation or initial operation. The built-in lubricant is designed for the entire service life and makes additional filling unnecessary.

Is there a recommended installation position for the right-angle gearbox?

All standard right-angle gearboxes can be mounted and installed in any orientation or mounting position. In addition, all standard Crown Gear Drives can either be fastened directly to the top of the housing with (3) screws or to the respective input and output shaft positions. The specific dimensions of the bore distance can be found in the catalogue.

For which areas of application are right-angle gearboxes with protection class IP65 intended?

Crown Gear Drives with protection class IP65 are equipped with shaft seals that prevent dust, dirt and water from entering the inside of the housing. The dust-tight product design prevents the ingress of splash water and is therefore ideal for applications that require protection against contamination and corrosion. A standardized, nickel-plated housing combined with food-safe lubrication (class H1) extends the range of applications and areas of use.

Common areas of application include:

- Food processing

- Ovens and dryers

- Packaging machinery

- Test equipment and test stands

- Special machine construction

What are the differences between a standard right-angle gearbox and an IP65 version?

The standard and the right-angle gearboxes with protection class IP65 are available with a transmission ratio of 1:1 and 2:1. All angular gearbox versions are designed for speeds of up to 2000 RPM as standard.

- Standard (black anodized aluminum housing, non-magnetic stainless steel shafts)

- IP 65 (nickel-plated aluminum housing, non-magnetic stainless steel shafts, shaft seals, food-safe lubrication)

What features do IP65 protection class right-angle gearboxes offer?

- High-quality, spiral bevel gears (AGMA class 10)

- Lubricated for life; maintenance-free

- Low backlash operation

- 1:1 or 2:1 transmission ratios

- 1 or 2 output shafts

- Nickel-plated gearbox housing and stainless steel shafts

- Counter-rotating versions available

Do right-angle gearboxes with IP65 protection class categorized as a special item?

All standard IP65 angular gearboxes are standard versions and are therefore available ‘ex stock’, i.e. long delivery times are not typically to be expected.

Are Zero-Max right-angle gearboxes suitable for use under water?

Standard Crown Gear Drives are not designed for underwater use. However, in the past we have been able to offer customized product solutions for this area of application, please contact us for further information.

How do I select the right design for my right-angle gearbox?

A number of factors must be taken into account when designing the correct right-angle gearbox. These include the preferred transmission ratio, the desired gearbox type (e.g. 3-way version), the area of application, etc. You can also find a corresponding guide in our product catalog.

- Determine Your Preferred Input/Output Ratio. Standard ratios are 1:1 and 2:1. It is also possible to use a step up ratio of 1:2

by using shaft #2 as the input shaft on 2:1 units. (See drawings on page 3-4 in the catalog). - Designate Which Shafts Are To Be Input And Output Shafts. This step is especially important to determine that no shaft will turn

faster than 2000 RPM. If shaft #2 in the 2:1 ratio models is selected as the input shaft, it can turn at a maximum of 1000 RPM.

In the 1:1 ratio models it makes no difference. However, the choice in either case will affect your mounting. - Choose Drive Type. Use either 2-way or 3-way configuration.

- Choose Style. Determine if Standard Models or IP65 Ingress Protection / Nickel-Plated Model is desired.

- Select The Correct Model Number. On pages 3–4 in the catalog, select the correct model number; note that units with 3/8 inch shafts have

flats and units with 1/2, 5/8, 3/4 and 1 inch shafts have standard keyways. Also note that 1 inch shaft models are available

in 3-way type only. - Be Certain That The Designated Output Shaft Has A Torque Capacity Greater Than Your Applications Load. Consult the tables on

the pages 5-6 in the catalog, and be sure to apply the service factors from the chart on page 8 in the catalog. - If modifications of shafts and/or housings are required for your application, send a drawing and a description of the

application to the factory.

The robust and reliable design of the Crown gear right-angle gearbox guarantees smooth operation and ensures a long service life. Easy installation and maintenance lead to high performance in demanding applications.

Standard 2-way and 3-way designs are available with gear ratios of 1 : 1 and 2 : 1.

- Shafts in stainless steel design

- Gear ratios 1 : 1 and 2 : 1

- Operating speeds up to max. 2000 rpm possible

- Innovative sealing technology enables maintenance-free operation

- Fully sealed bearings

- Multiple mounting positions possible

Do you have any questions? We look forward to hearing from you!