Higher performance by using a CD coupling

Zero-Max application engineers met the challenge with a customized CD coupling. The original packaging system gearbox and driveline did not use a CD Coupling and had excessive torsional compliance. When the system accelerated and decelerated, a torsional windup occurred between the system’s large diameter turntable and the servomotor position. The windup was causing a rotational “bounce” when stopping the turntable, requiring a settling time, which reduced throughput on the machine.

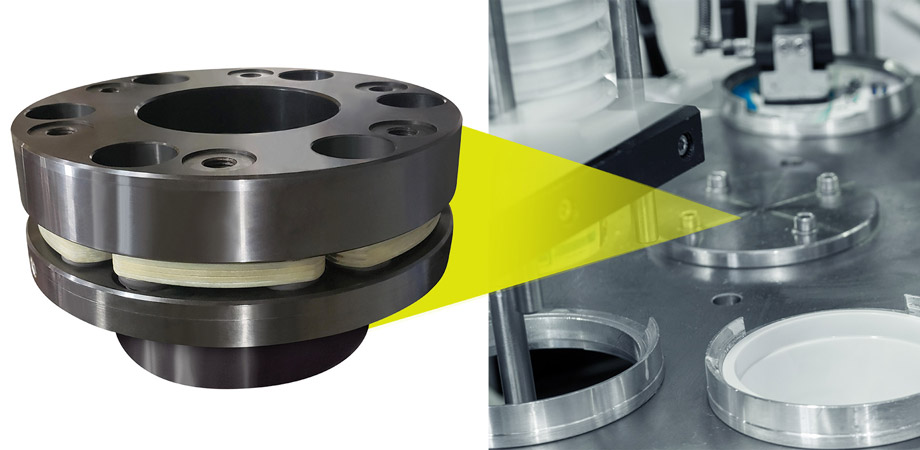

A stiffer gearbox and a coupling with higher torsional stiffness were needed. The customer chose a flanged gearbox which eliminated an output shaft and one source of compliance. This design allowed Zero-Max to substitute a flange adaptor to its field-proven CD coupling in place of the standard coupling hub. This design simplified the driveline with fewer components and improved the performance. Also, a special extra-stiff CD disc pack was added to the modified coupling, providing the extra torsional stiffness needed, allowing for increased volume throughput of the machine.

CD Coupling Improves Performance While Eliminating Problems

The customized CD Coupling provided a straight-forward solution. It was easy to install by simply removing the failed coupling and connecting the new CD Coupling’s flanged hub design in the system’s power train, without having to redesign or relocate any machine components.

Coupling Expertise Makes A Big Difference

Zero-Max often utilizes Finite Element Analysis in the design of custom disc packs and reviews various application requirements such as torque, speed, torsional stiffness, misalignment and dimensional fit to ensure a proper design is made for high performance and long lifetime in challenging applications.

Custom designs from Zero-Max include couplings handling high power and precision in a small space envelope, large scale floating shaft couplings, high misalignment and high torque couplings, high speed couplings, high precision couplings – plus many more.