Roh'Lix linear actuator - no roll backwards in terms of hygiene

The Zero-Max Roh’Lix linear actuator product range benefits from the optional stainless steel version, particularly for applications with a high level of cleanness and constantly increasing requirements in hygiene-related areas of application.

Functionality:

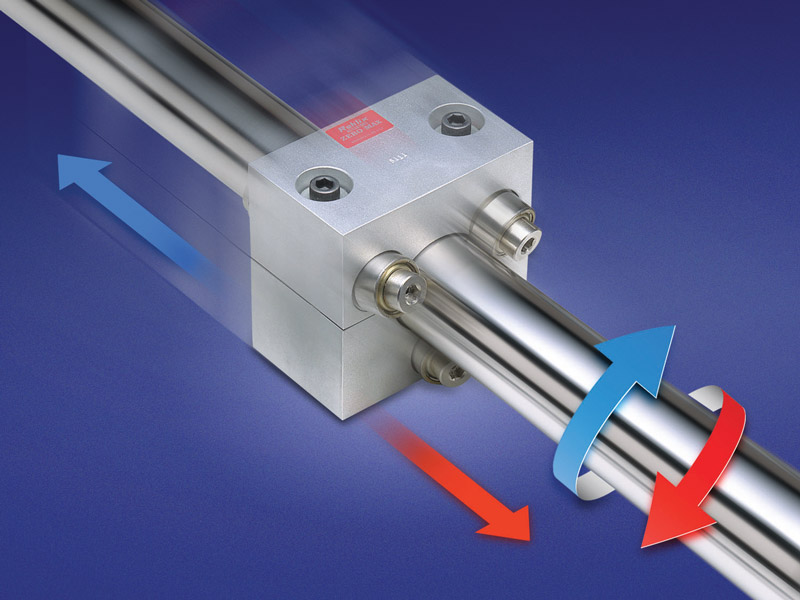

The unique product feature of the Roh’Lix consists of the converting of rotary motion into linear motion, whereby linear travel speeds of 1750mm/sec. can be achieved, depending on the size of the assembly. The functionality of the actuator corresponds largely to that of a ball screw. In contrast to a ball screw, the Roh’lix slides on a smooth shaft and also offers an overload protection function.

Based on the linear actuator product design, in most cases this results in a significantly higher resistance to contamination and dirt compared to classic ball screws. If the pre-adjusted, permissible linear thrust force setting is exceeded, the linear movement is halted. This function offers additional protection for processes in which people are involved.

Product design:

The precision actuators consist of three replaceable stainless steel bearings positioned on both sides at the end of the housing. The product design with the six bearings, which are equipped with a specific angle to the linear axis, achieves a minimum efficiency of 90%. Depending on the area of use and application, linear travel distances of up to 2,500,000 meters can be achieved, ideally significantly more.

Zero-Max Roh’Lix stainless steel versions are ideal for the following sectors and industries:

- Food industry

- Pharmacy

- Medicine

- Packaging

- Applications with frequent cleaning processes

General product features:

- Compact design

- Integrated overload function

- Use on smooth shaft

- Individual lead from 0.625 mm to 150 mm possible

- Standard thrust range from 67 Nm to 889 Nm

- Shaft diameter from ø8 mm to ø50 mm

- High service life expectancy

- Tandem operation possible

- Use in horizontal and vertical installation position

- Easy handling (installation, operation)

- Maintenance-free and dry operation

- High resistance to contamination

- High level of customization

- Many other unique product features