“Floating Shaft” CD® Couplings From Zero-Max

Shock Proof Reciprocating Motion In High Speed Servo Powered Partition Inserters From Wayne Automation

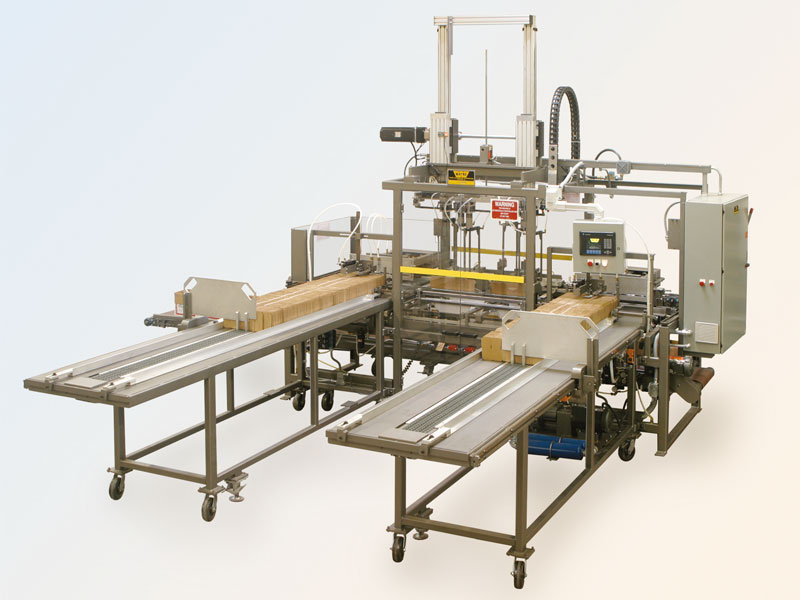

Newly introduced Partition Inserters (Model SF-400) from Wayne Automation Corporation cycle once every second and travel 38 inches vertically. Every up/down cycle accurately inserts solid fiber or corrugated partitions into cartons that hold bottles and plastic containers ready for shipment to the marketplace.

How do these Wayne inserters maintain repeatable accuracy 24/7 at these high speeds? The answer is their robust innovative design using servomotors connected to backlash-free Zero-Max CD couplings. These couplings damp out shock and vibration from the inserter’s vertical reciprocating and intermittent motion and maintain insertion accuracy cycle after cycle.

Trouble-free, high-speed insertion cycles are assured by the robust drive design using servomotors connected to backlash-free Zero-Max Floating Shaft CD Couplings. They equalize tension on right and left timing belts pictured above.

Partition Inserter for Die Cut Blanks.

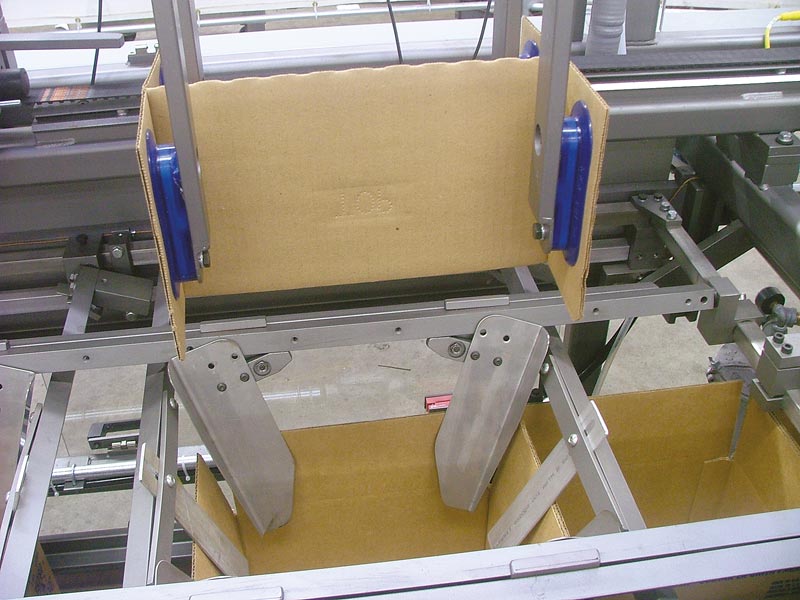

“To operate without problems, conventional vertical inserters require near perfect fiber or corrugated partitions,” reports Jay Bachman, vice president of engineering for Wayne Automation. “In contrast, the SF-400 inserters have designed-in features, including servo drive systems, that help deal with less than perfect materials. Unlike conventional systems which rely on gravity during the insertion process, the SF-400 maintains complete insertion control from the time the partition is picked off the magazine until is fully inserted into the case. This ensures correct partition placement into the case every cycle.”

Wayne Automation Corporation has been building innovative packaging machinery for 30 years. The company is widely known as the premier supplier of partition handling equipment to the glass and plastic container industry. Its case erecting equipment, for example, is backed by a guarantee to operate with less than 1/8th of 1 percent material loss and efficiencies of 99 percent or better. With this reputation, the company strives to design its motion systems with components that will deliver with unfailing reliability.

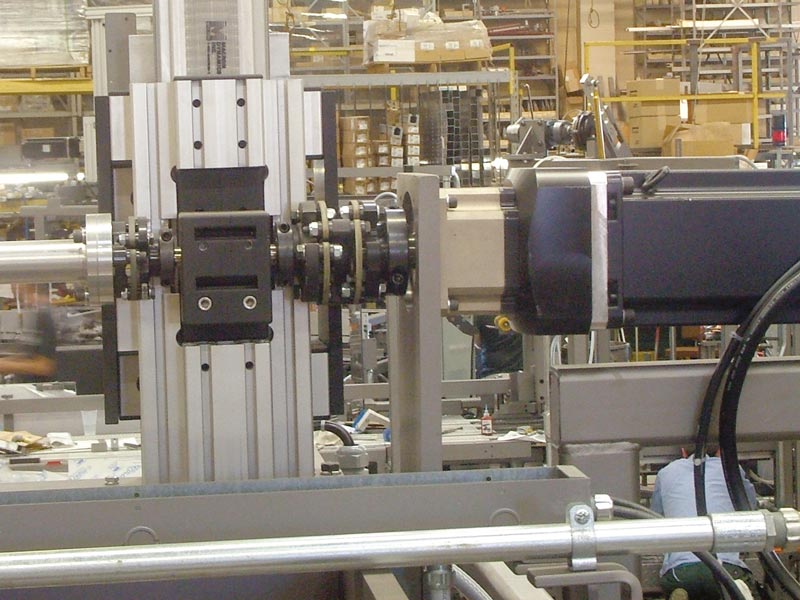

Two Servo Driven Timing Belts Synchronized With Help From

Floating Shaft CD Coupling – Smoothes Inserter’s Start/Stop Cycling

The drive system for the SF-400 vertical inserter mechanism is powered by an Allen Bradley servomotor connected to a planetary reduction gearbox. The motor transmits torque to the inserter via a “floating shaft” Zero-Max CD coupling configuration connected at both ends to two gearboxes. These gearboxes are connected to two timing belt drive pulley gearboxes.

“The combination of both intermittent and reciprocating motions at 1000 rpm (38 inch one-way travel for every 1 second cycle) is very demanding on the system’s drive train,” Bachman reported. “Torque loads are a big factor in this setup with cyclical peak torques approaching 60 percent of the motor torque with vertical load lift up to 200 lbs. We needed a coupling design that would handle these forces and one that we could position at both ends of the two gearboxes to equalize tension on both timing belts.

We chose the Zero-Max CD 6F30-AC floating shaft coupling. We have confidence in CD couplings and have incorporated them in our system designs for nearly 10 years because of their unique performance features and dependability. They operate very well with servomotors and have become a key design element in our systems from the time we transitioned from air cylinder actuation to servo drives. Servo drives are energy saving, more reliable and require less maintenance and the use of the CD couplings are important contributors to those benefits.”

Intermittent Motion Controlled By Zero-Max CD Coupling

The Wayne SF 400 coupling application is unique because of the 28 inch span from one coupling’s outer connecting hub to the second coupling’s outer hub. Also, this setup is a real test of each coupling’s patented composite disc design integrity that has a rated torque of 800 in. lbs (90 Nm). With similar features to other good coupling designs, the CD coupling has one critical difference – its patented composite disc pack design. There’s nothing else like it in the coupling world.

While the CD coupling disc pack transmits torque similar to any conventional coupling, it does a better job of dampening backlash and shock without coupling fatigue, which can occur in a fast-moving, high torque system like the SF 400. The disc pack at each shaft end resists fatigue through its patented open arm disc design. Made of highly durable composite material, the disc pack absorbs any shock from the servomotor’s intermittent motion while maintaining a zero backlash condition. Also, the coupling’s disc design and hub configuration provide excellent support for the floating shaft component without imposing excessive radial loads on the connected equipment and bearings. Precision machining of the coupling components also gives the connection good dynamic balance for smooth, quiet operation.

The Zero-Max Floating Shaft CD Coupling is zero-backlash and torsionally stiff. It provides support for the floating shaft component without imposing excessive radial loads on connected equipment and bearings.

CD Coupling disc pack provides greater flexibility, misalignment, longer life, and damps shock and vibration through its unique patented open arm design with the use of highly durable composite material.

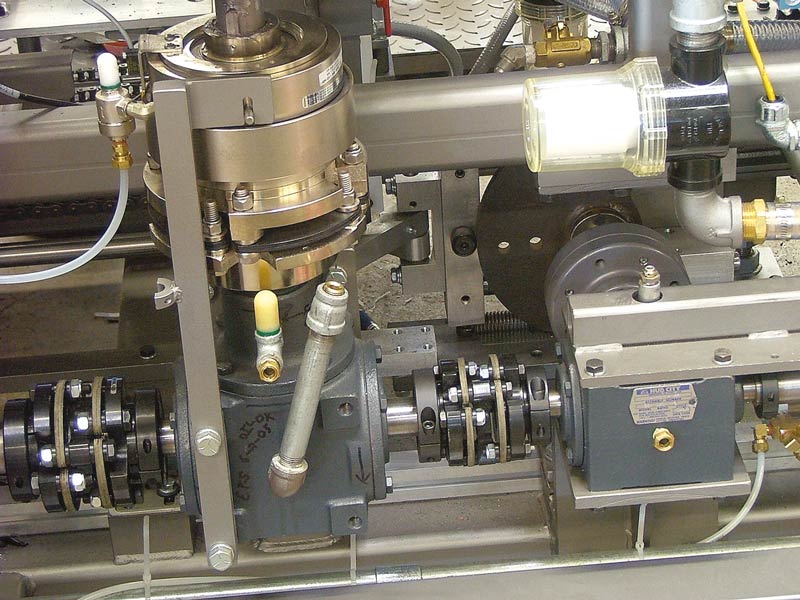

Companion Erector System Utilizes CD Couplings In Power Train/Clutch Mechanism

High speed is also a key feature of Wayne Automation’s VCE model case erector systems which assemble corrugated cartons at the rate of 80 cartons a minute. Controlling motion in these systems with CD Couplings is equally important as in Wayne Automation’s inserters. The VCE case erectors employ CD couplings mounted to gearbox shafts.

Two are standard model 6F45 couplings that transmit horizontal rotary motion and provide zero backlash during operation and also when the system’s clutch mechanism is actuated. This clutch mechanism is positioned on the vertical shaft of the gearbox and is comprised of a torque limiting clutch assembly and a special Zero-Max CD coupler. This device allows an operator to manually stop and restart the feeding mechanism as containers finish travel through the system to complete a case packer run.

“Overall, CD couplings give our systems excellent performance and service life having replaced jaw and other type couplings a decade ago. The CD coupling was our first choice for the new SF-400 and it has proved very functional,” Bachman concluded.

For more information on Wayne Automation case erectors and inserters, call 610-630-8900. Website: www.wayneautomation.com, Email: sales@wayneautomation.com or write to Wayne Automation Corporation, 605 General Washington Avenue, Norristown, PA 19403.