Zero-Max Overhung Load Adaptor - Outrigger Bearing Assembly Hidden Champion

Why an OHLA can provide real added value for a wide range of demanding applications!

Customised adaption to the application requirements:

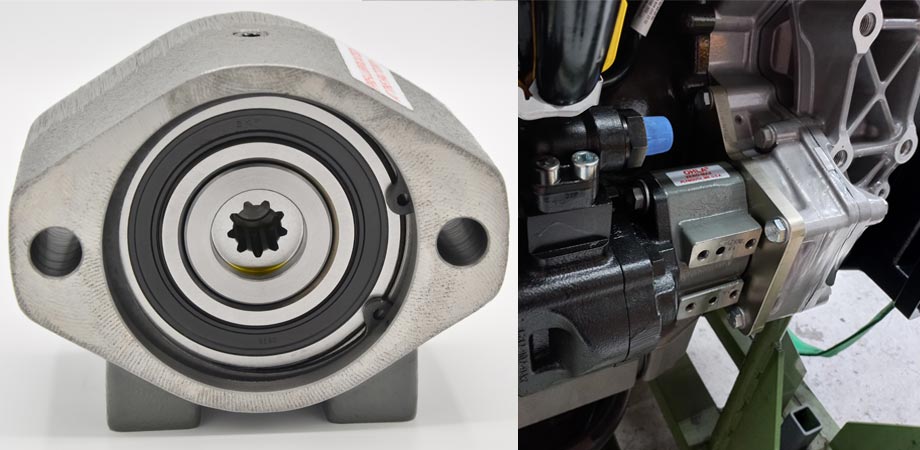

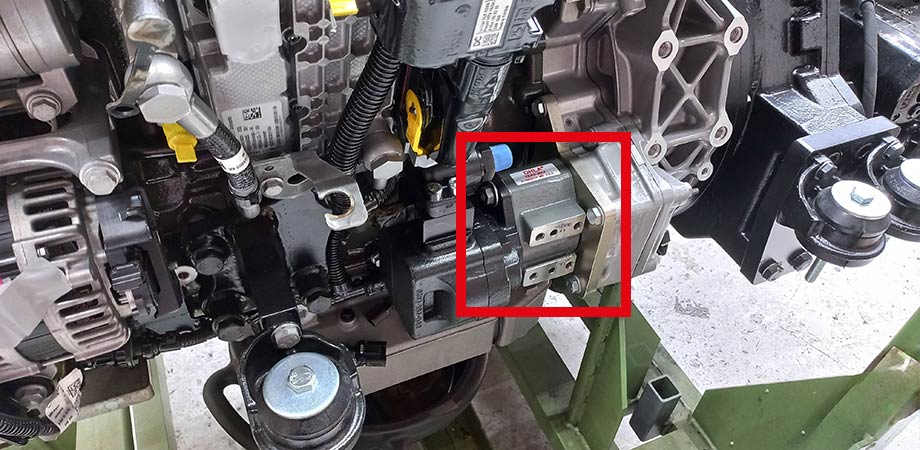

The Overhung Load Adaptor (OHLA) in the installed system can be seen in a current application example from a customer in the German-speaking region. Here, the customised OHLA ensures safe operation between a pump that drives the fan and the engine. The challenge was to create a special connection to the diesel engine, which had no direct connection to the hydraulic pump. In addition to limited installation space dimensions, modified output shaft properties had to be taken into account. Finally, the desired PTO splines (9 teeth 16/32 splines) could be realised according to customer requirements. After calculating the known technical parameters, a service life expectancy of over 10,000 working hours was determined for the specified application..

Further technical specifications of the application:

- Maximum pump speed: 3000 rpm

- Pump flow rate: 20 l/min

- Power consumption in operating mode: 8.4 kW at 1600 rpm

Background story behind the product ‘OHLA’:

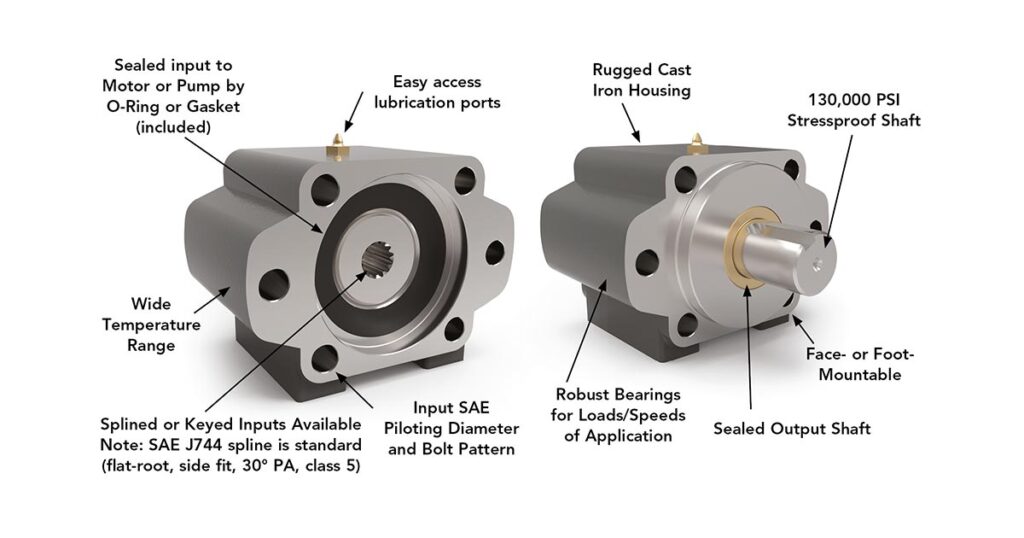

The Zero-Max Overhung Load Adaptor was officially added to the product portfolio in 1990 with the acquisition of Helland Research and Engineering. Even then, it was clear that this product series could have a remarkable rise. In the years and decades that followed, the requirements and application areas placed on products became increasingly challenging and demanding. The constant modification and improvement of the Overhung Load Adaptor was and is the guarantee for impressive product development.

From the first draft to the customised solution:

The versatility of this product enables it to be used in a wide range of applications. The use of Overhung Load Adaptors in mobile hydraulic systems promises unique product features combined with a high range of customisation options to suit the application requirements.

Curiosities:

- The term ‘Overhung Load Adaptor’ (OHLA) is a term that is only used regionally, even in the USA, and is therefore rather unknown.

- The OHLA product range comprises 24 sizes, which are divided into more than 70 different versions, yet more than 70 % of all products sold worldwide are customised versions.

- The comparison is often made with a classic bearing system, which is only valid to a very rudimentary level. There is no comparable product with identical product characteristics in Europe. (on behalf)

Common areas of application include:

- Mulchers

- Harvesters

- Harvesting machines (beets, nuts, grapes, etc.)

- Shredders/chippers

- Trimmers

- General adaptations of different assembly standards (e.g. SAE A to SAE B)

- Vegetation maintenance

- Drilling systems

- trimmers

- General fan support systems

- Felling machines

- Stone crushers/rock crushers

- Clearing/grubbing

- Slurry spreading